TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 272 of 528

TM 9-2330-356-14

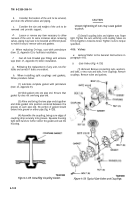

(b)

The clearance should be between

0.070-inch and 0.120-inch (as near to 0.070-inch as

possible).

(c)

Adjust the link screw on the end of the

solenoid plunger for proper clearance.

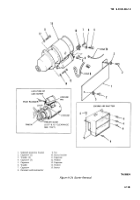

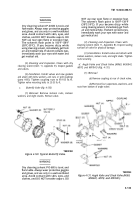

(2) Raise engine air shutter and position the

starter motor and shield on engine. Install top retaining

capscrew (11) and washer (12) on starter. Using a 3/8-inch

drive set, long extension, universal joint, and a 9/16-inch

universal socket, install bottom starter capscrew (13) and

washer (14).

(3) Secure starter support bracket to starter

using capscrew (7), washer (8), and nut (9). Do not tighten.

(4) Using capscrew (5) and washer (6) secure

starter support bracket to engine. Tighten capscrew (7),

washer (8), and nut (9).

solenoid.

shutter.

(fig, 4-37).

(5)

Attach leads No. 74 and No. 6 to starter

(6)

Replace the five capscrews (4) on engine air

(7)

Connect negative battery cable to battery

4-80. Starter Solenoid

WARNING

When performing electrical maintenance,

ALWAYS disconnect intervehicular electrical

cable from semitrailer, and negative battery

cables at batteries. Failure to follow this

warning may create a spark and explosion,

resulting in serious injury or death to

personnel.

a.

Removal.

(1) Remove negative battery cable from battery

(fig. 4-37).

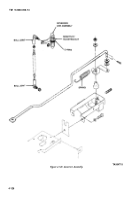

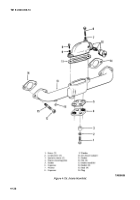

(2) Starter solenoid removal must be done from

underneath the vehicle on the left side of the engine.

(3) Remove starter solenoid protective bracket

(1) by removing the two retaining capscrews (2) and

washers (3).

(4) Remove hot lead No. 6 from large bottom

pole of solenoid and lead No. 74 from small pole.

(5) Remove linkage pin which connects solenoid

shaft to linkage (fig. 4-124).

(6) Remove two screws that fasten solenoid to

starter motor. Remove solenoid.

b.

Installation.

(1) Position starter solenoid on starter motor and

fasten with two screws.

(2) Connect starter linkage to solenoid using

linkage pin.

(3) Attach hot lead No. 6 to large bottom pole of

solenoid and lead No. 74 to small pole.

(4) Replace starter solenoid protective shield.

Fasten with two capscrews and washers.

(5) Connect negative battery cable to battery

(fig. 4-37).

4-81. Buss Bar

WARNING

When performing electrical maintenance,

ALWAYS disconnect intervehicular electrical

cable from semitrailer, and negative battery

cables at batteries. Failure to follow this

warning may create a spark and explosion,

resulting in serious injury or death to

personnel.

a.

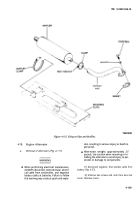

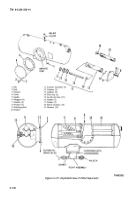

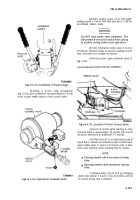

Replacing Buss Fuse (Fig. 4-125).

(1) Disconnect negative battery cable from

battery (fig. 4-37).

(2) Remove buss bar cover (fig. 4-125) by

removing two capscrews and nuts.

(3) Remove buss bar fuse from its clips.

(4) Install new fuse between clips.

(5) Replace buss bar cover. Attach to firewall

with two capscrews and nuts.

(6) Reconnect negative battery cable to battery

(fig. 4-37).

b.

Removal.

(1) Perform steps (1) through (3) of paragraph

a.

(2) Disconnect all electrical leads from buss bar.

4-136

Back to Top