TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 263 of 528

TM 9-2330-356-14

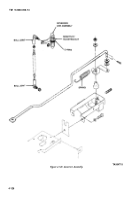

d.

Installation.

(1) Remove screw, handle, packing nut, one nut,

and washer from handle end of cable.

(2) On opposite end remove one jam nut.

(3) Install cable through channel of control

panel. Replace the jam nut, packing nut, handle, and

screw.

(4) Thread cable through hole in engine

shrouding. Replace inside jam nut (fig. 4-107), but do not

tighten.

(5) Replace jam nut and yoke and attach yoke to

throttle rod with clevis pin and cotter pin.

(6)

(7)

(step

b).

(8)

(9)

Start engine (para 2-10).

Adjust engine speed to low idle (900 rpm)

Shut off engine (para 2-10).

Replace engine cover panel.

(10) Replace straps.

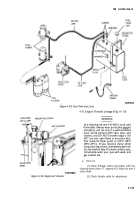

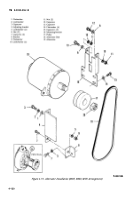

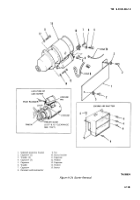

4-76. Governor Assembly (Fig. 4-109)

a.

Service.

WARNING

Dry cleaning solvent P-D-680 is toxic and

flammable. Always wear protective goggles

and gloves, and use only in a well-ventilated

area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat.

The solvent’s flash point is 100°F-138°F

(38°C-59°C). If you become dizzy while

using cleaning solvent, immediately get fresh

air and medical help. If solvent contacts eyes,

immediately wash your eyes with water and

get medical aid.

(1) Clean all accessible linkage with dry cleaning

solvent (item 11, Appendix E). Wipe dry with a clean cloth.

(2) Periodically lubricate the ball joints

(fig. 4-109) with OE-10 oil (item 21, Appendix E).

Remove the engine panel door (fig. 4-101) to gain access

to the ball joints.

b.

Governor Sensitivity Adjustment (No Engine Surge).

(1) Start engine (para 2-10).

(2) Locate access hole cover on side of engine

blower housing and remove cover (fig. 4-101).

(3) Locate the governor arm assembly

(fig. 4-109).

(4) For a coarse adjustment, relocate the spring

in the notches in the governor arm.

(5) For a fine adjustment, insert a screwdriver

through the access hole to ratchet-type base of the

governor arm. Turn the ratchet hub clockwise to decrease

sensitivity or counterclockwise to increase sensitivity.

(6) Adjust for maximum sensitivity without a

surging condition.

(7) Stop engine (para 2-10).

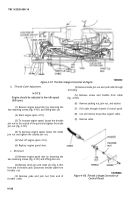

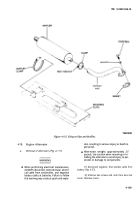

4-77. Engine Muffler/Exhaust

a.

Removal (Fig. 4-110).

(1) Remove muffler shroud by removing ten

capscrews that secure shroud to panels (fig. 4-101).

(2) Loosen clamp (fig. 4-110) on the exhaust

pipe by loosening a bolt and a nut.

(3) Remove two muffler clamps securing muffler

to mounting plate. Remove muffler.

(4) Remove two capscrews and lockwashers from

the exhaust pipe at the manifold. Remove exhaust pipe

adapter and gasket.

b.

Installation (Fig. 4-110).

(1) Install a new gasket between exhaust pipe and

exhaust manifold. Secure exhaust pipe and adapter to

manifold with two capscrews and lockwashers.

(2) Put exhaust pipe clamp over end of exhaust

pipe and insert muffler inlet into exhaust pipe. Do not

tighten clamp.

(3) Replace muffler clamps and tighten.

(4) Tighten exhaust pipe clamp.

(5) Replace muffler shroud, securing with ten

capscrews (fig. 4-101).

4-127

Back to Top