TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 277 of 528

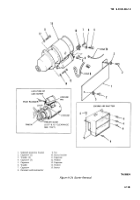

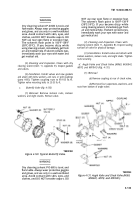

(8) Install new gasket (5).

(9) Replace cover (4). Secure with twelve bolts

(2), washers (3), and nuts (1). Ensure that four bolts with

holes in shaft are installed where lead seal wires will be

installed.

(10) Install one lead seal wire through holes in top

pair of bolts (2) and one through holes in bottom pair. Put

wires through seals and crimp, using tool, Lead Seal Press,

NSN 5120-00-224-7592. Trim excess wire.

4-84. Sump Components

WARNING

Read and observe all safety precautions

listed in the Warning Summary before per-

forming maintenance on sump components.

Ensure that semitrailer is grounded to an ap-

proved (earth) ground and it is safe to pro-

ceed. Failure to follow this warning may

cause a spark to ignite, resulting in serious in-

jury or death to personnel.

a.

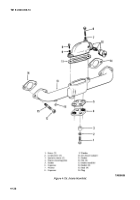

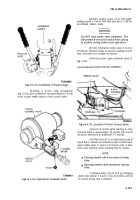

Automatic Drain Valve and Float Assembly.

(1)

Removal.

(a)

Close valve M.

(b)

Place a suitable container under the

manual drain valve N (fig. 4-127). Open valve N and

remove air fluid from filter/separator. When thoroughly

drained, close valve N.

NOTE

DO NOT disconnect the tubes connecting the

float assembly to the automatic drain valve.

(c)

Disconnect the tube coming from top of

filter/separator at the float assembly. Only the M970 and

M970A1 have a second tube to be disconnected.

assembly.

(e)

(f)

assembly.

TM 9-2330-356-14

(d)

Remove the eight capscrews and

washers that fasten the float assembly to the

filter/separator. Remove float and automatic drain valve

Remove and discard gasket.

Remove manual drain valve from the

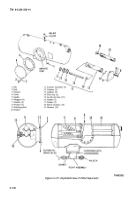

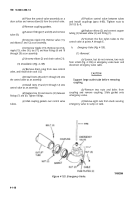

(2)

Installation.

(a)

Place a new gasket on flange of float

assembly.

(b)

Install float and automatic drain valve to

filter/separator. Attach with eight capscrews and washers.

Tighten securely.

(c)

Connect the tube line(s) to the float

assembly.

b.

Replacement of Manual Drain Valve.

(1) Close valve M.

(2) Place a suitable container under the manual

drain valve N (fig. 4-127). Open valve N and remove all

fluid from filter/separator.

(3) Unscrew manual drain valve from float

assembly. Be sure nipple does not come off with drain

valve.

NOTE

Be sure manual drain valve is closed.

(4) Screw manual drain valve tightly onto nipple

of float assembly.

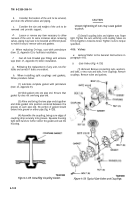

Section XIX. MAINTENANCE OF DISPENSING EQUIPMENT

4-85. General

ment. Ensure that semitrailer is grounded to

an approved (earth) ground and it is safe to

proceed. Failure to follow this warning may

WARNING

cause a spark to ignite, resulting in serious in-

jury or death to personnel.

Read and observe all safety precautions

listed in the Warning Summary before per-

a.

Read and observe all safety precautions in the

forming maintenance on dispensing equip-

Warning Summary.

4-141

Back to Top