TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 282 of 528

TM 9-2330-356-14

(m)

Shut off engine (para 2-10).

(n)

Replace plastic plug in needle valve.

(o)

Remove gage from underwing nozzle

and stow nozzle.

(2)

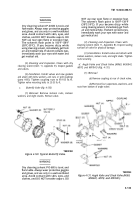

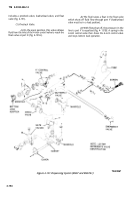

Removal.

(a)

Disconnect the two nylon tubes from the

4-inch control valve at points A and B (fig. 4-135).

(b)

Remove the two nuts and bolts from the

two couplings (fig. 4-135) and remove the couplings. Slide

gaskets onto mating pipes and remove the control valve

assembly.

(c)

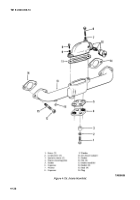

Place control valve assembly on a clean

surface and remove tube elbow (1, fig. 4-136) from control

valve.

(d)

Unscrew tee (3) from control valve and

remove tee (3), drain cock (2), and tube fitting (4) as an

assembly.

(e)

Unscrew drain cock (5) from control

valve.

(3)

Installation.

(a)

Remove drain plug from new control

valve and install drain cock (5) (fig. 4-136).

(b)

Install drain cock (2), tee (3), and tube

fitting (4) assembly onto control valve.

(c)

Install tube elbow (1) onto control valve.

TA099867

Figure 4-136. Removal of Fittings From 4-Inch

Control Valve.

(d)

Position control valve, and slide

coupling gaskets over valve ends (para 4-85). Install

couplings.

(e)

Connect the two nylon tubes (fig. 4-135)

at A and B.

g.

3-inch Control Valve (Deadman Valve) (M970 and

M970A1).

(1)

Adjustment.

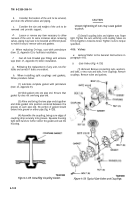

(a)

Locate needle valve (fig. 4-137) and

remove plastic plug.

(b)

Using a 4-inch-long screwdriver, close

needle valve (fig. 4-134) completely by turning adjusting

screw clockwise.

(c)

When closed, turn adjusting screw five

turns counterclockwise to adjust valve to proper setting.

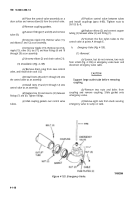

TA099868

Figure 4-137. Location of Needle Valve.

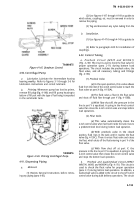

(2)

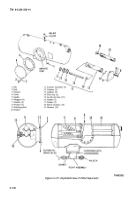

Removal (Fig. 4-138).

(a)

Disconnect and tag the five nylon tubes

from the control valve at points A through E.

(b)

Loosen fitting (1) and elbow (2), and

remove copper tubing (3).

(c) Remove two nuts from each of two

couplings (4 and 5) and remove the couplings.

(d)

Slide the coupling gaskets onto the

control valve and remove the control valve assembly.

4-146

Back to Top