TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 281 of 528

TM 9-2330-356-14

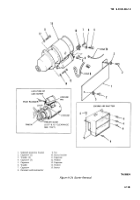

TA099863

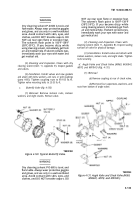

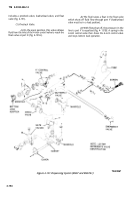

Figure 4-133. Installation of Pressure Gage.

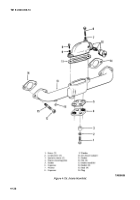

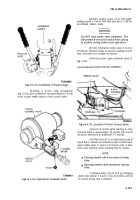

(f)

Using a 4-inch long screwdriver

(fig. 4-134), turn screwdriver counterclockwise 8-10 full

turns to open needle valve on 4-inch control valve.

(g)

Start engine (para 2-10) and begin

loading (para 2-14a for self-load and para 2-13b for

non-filtered bottom load).

WARNING

DO NOT close needle valve completely. This

will prevent 4-inch control valve from closing

at anytime during bottom load operations.

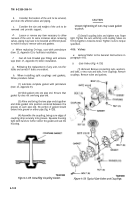

(h)

Close (clockwise) needle valve in ¼-turn

increments. Observe change in pressure reading at each

step, until there is no change in pressure.

(i)

At this point, open precheck valve D

(fig. 2-26).

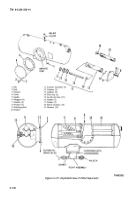

TA099866

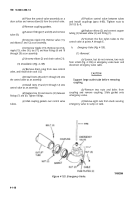

Figure 4-135. Location of 4-Inch Control Valve.

Figure 4-134. Adjustment of Needle Valve.

TA099864

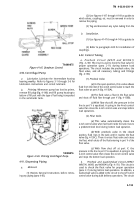

(j)

Sound of control valve starting to close

should be heard in approximately

30 seconds. Full shut off

should be obtained in an additional 3–5 seconds.

(k)

If full shut off is not obtained (sound of

liquid flow or whistle are indications) open (counterclock-

wise) needle valve in ¼-turn increments until it does.

Then close precheck valve, allowing flow to resume.

NOTE

Closing needle valve increases closing

time.

Opening needle valve decreases closing

time.

(1) Repeat steps

(h), (i),

and

(j),

changing

needle valve setting in ¼-turn or less increments until the

3-5 second closing rate is obtained.

4-145

Back to Top