TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 280 of 528

TM 9-2330-356-14

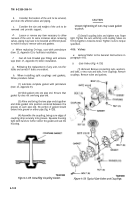

(c)

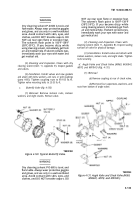

Remove angle valve and check valve as a

complete assembly.

(d)

Separate check valve and angle valve on

a bench by removing four capscrews, washers, and nuts.

WARNING

Dry cleaning solvent P-D-680 is toxic and

flammable. Always wear protective goggles

and gloves, and use only in a well-ventilated

area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat.

The solvent’s flash point is 100°F-138°F

(38°C-59°C). If you become dizzy while

using cleaning solvent, immediately get fresh

air and medical help. If solvent contacts eyes,

immediately wash your eyes with water and

get medical aid.

(2)

Cleaning and Inspection.

Clean with dry

cleaning solvent (item 11, Appendix E). Inspect gaskets

and valves.

(3)

Installation.

(a)

Assemble angle valve, new gasket, and

check valve assembly by securing both valves together with

four capscrews, washers, and nuts.

(b)

Position angle valve and check valve

between manifold and pipe. Install new gasket, four

capscrews, washers, and nuts to secure angle valve to

manifold. Do not tighten capscrews.

(c)

Install coupling and gasket (para 4-85h).

Tighten coupling nuts to 57-63 lb.-ft.

(d)

Tighten capserews securing angle valve

to manifold to 25-35 lb.-ft.

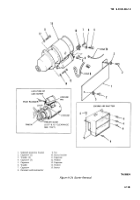

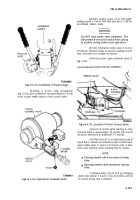

e.

Check Valve (M967, M967A1, M969, and M969A1)

(Fig. 4-132) .

(1)

Removal.

Remove sixteen capscrews,

washers, and nuts. Remove valve and gaskets.

WARNING

Dry cleaning solvent P-D-680 is toxic and

flammable. Always wear protective goggles

and gloves, and use only in a well-ventilated

area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat.

The solvent’s flash point is 100°F-138°F

(38°C-59°C). If you become dizzy while

using cleaning solvent, immediately get fresh

air and medical help. If solvent contacts eyes,

immediately wash your eyes with water and

get medical aid.

(2)

Cleaning and Inspection.

Clean with dry

cleaning solvent (item 11, Appendix E). Inspect gaskets

and valves.

(3)

Installation.

Install valve and new gaskets with

sixteen capserews, washers, and nuts. Tighten nuts to

25-35 lb.-ft.

Figure 4-132. Check Valve (M967, M967A1, M969,

and M969A1).

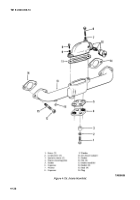

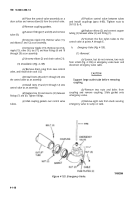

f.

4-Inch Control Valve (Bottom Loading)

(Figs. 4-134 and 4-135).

TA099862

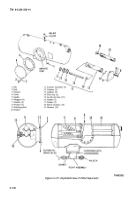

(1)

Adjustment (to ensure that fuel shut-off closes).

(a)

Start with empty tank.

(b)

Refer to flow diagram for either filtered

self-load (fig. 2-34) or non-filtered bottom load

(fig. 2-22).

(c)

Install a 0-60 psi pressure gage in the

3/8-inch NPT port on underwing nozzle (fig. 4-133) for

filtered self-load or non-filtered bottom load.

(d)

Connect underwing nozzle (for

self-load) or storage facility hose to the bottom load

adapter (figs. 4-147 through 4-149).

(e)

Remove plastic plug (fig. 4-134) from

needle

valve.

4-144

Back to Top