TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 278 of 528

TM 9-2330-356-14

b.

Consider the location of the unit to be serviced,

and drain the affected valves and piping.

c.

Consider the size and weight of the unit to be

removed and provide support.

d.

Loosen or remove any item necessary to allow

removal of the unit. In some instances when removing

valves, piping may have to be loosened at different places

to make it easy to remove valve and gaskets.

e.

When replacing O-rings, coat with petrolatum

(item 23, Appendix E) to facilitate installation.

f.

Coat all male threaded pipe fittings with antiseize

tape (item 27, Appendix E) before installation.

g.

Following the replacement of any unit, test for

leaks and correct if leaks are evident.

h.

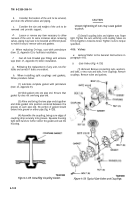

When installing split couplings and gaskets,

follow procedure below:

(1) Lubricate complete gasket with petrolatum

(item 23, Appendix E).

(2) Slide gasket onto one pipe end. Ensure that

gasket lip does not overhang pipe end.

(3) Aline and bring the two pipe ends together

and slide gasket into position centered between the

grooves on each pipe end. No portion of gasket should

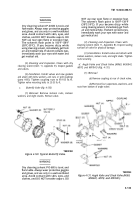

extend into groove on either pipe (fig. 4-128).

(4) Assemble the coupling, being sure edges of

coupling drop securely into grooves. Squeeze housing

tight with hands to further center the gasket and seat the

housing.

TA502383

Figure 4-128. Installing Coupling Gasket.

CAUTION

Uneven tightening of nuts may cause gasket

to pinch.

(5) Install coupling bolts and tighten nuts finger

tight. Tighten the nuts uniformly until coupling halves are

firmly together–metal-to-metal. Tighten nuts to torque

specified.

4-86. Valves

a.

General.

Refer to the General Instructions in

paragraph 4-85.

b.

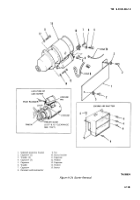

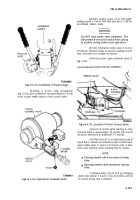

Gate Valves (Fig. 4-129).

(1)

Removal.

Remove connecting nuts, washers,

and bolts, or two nuts and bolts, from couplings. Remove

couplings. Remove valve and gaskets.

Figure 4-129. Typical Gate Valves and Couplings.

TA099859

4-142

Back to Top