TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 295 of 528

TM 9-2330-356-14

(2)

Float Valve.

secondary air reservoir to operate a normally closed pilot

valve A on the 3-inch control valve.

(a)

This valve automatically closes the

4-inch control valve when fuel level inside tank rises to a

predetermined level during bottom load operation.

(b)

With precheck valve in the closed

position, fluid rises in the tank until it reaches the float

valve (fig. 4-151C).

(c)

There it enters float valve and raises the

float which shuts off the fluid entering in port Y of the

float valve (load/unload valve must be in load position).

(d)

With flow shut off at port Y the pressure

in the line to port Y is equalized. A spring in the 4-inch

control valve then closes the 4-inch control valve and stops

the bottom load operation.

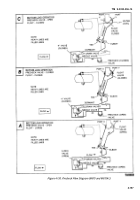

(3)

Load/Unload Valve.

(a)

Unlike the M970 and M970A1, the

M967, M967A1, M969, and M969A1 do not provide a

means to manually shut down flow to the 4-inch control

valve during bulk delivery operations.

(b)

During these operations, fuel exiting the

pump will follow two paths; one to either the piping

control or the filter/separator (dependent on operation)

and the other to the 4-inch control valve.

(c)

When the fuel reaches the 4-inch

control valve inlet, the valve opens and allows fuel to

follow a path back to the pump. Consequently, the pump

actually recirculates the fuel in the piping system.

Therefore, when performing bulk delivery operations, the

load/unload valve is switched to the unload position. This

closes the load/unload valve and disrupts the flow in the

line to port Y on the float valve before it reaches the float

(fig. 4-151D).

(d)

Because the load/unload valve is

connected in series in the line to port Y, when precheck

operation or loading operations are performed, the

load/unload valve must be in the load (open) position

(fig. 4-151A and 4-151B).

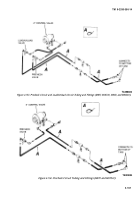

c.

Deadman Control Circuit (M970 and M970A1)

(Fig. 4-152).

(1) When the underwing nozzle is used in

conjunction with the 2½-inch hose reel, the deadman

control is used to control the fuel flow through the

underwing nozzle.

(2) The deadman control S (fig. 4-152) is a

hand-held control which uses air pressure from the

(3) When the normally closed pilot valve A is

closed, fuel from the inlet side of the 3-inch control passes

through a needle valve and into the 3-inch control valve

spring chamber. It also passes through normally open pilot

valves B and C on its way to the manifold.

(4) Fuel also flows through the 3-inch control to

the 2½-inch hose reel.

(5) As it enters the hose reels, fuel is bled off

through a pilot line, through the check valve portion of

deadman release valve, to the normally-open pilot valve

B.

(6) The fuel pressure closes pilot valve B,

creating pressure in the spring chamber of the 3-inch

control valve. The additional pressure created on the

valve poppet of the 3-inch control valve closes the valve,

stopping flow to the underwing nozzle.

(7) To open the control valve, the trigger on the

deadman control is squeezed, and air from the secondary

air reservoir is directed to the normally-closed pilot valve

A to open the pilot valve.

(8) Once Valve A is open, the pressure in the

spring chamber of the 3-inch control valve is relieved and

the control valve opens.

(9) When the water level in the filter/separator

sump is high enough to raise the float in the automatic

drain valve, pilot pressure is sent through the pilot line

from the automatic drain valve to the pilot valve C.

(10) The pilot valve C closes, creating pressure in

the spring chamber of the 3-inch control valve.

(11) The additional pressure created on the valve

poppet of the 3-inch control valve closes the valve,

stopping flow to the underwing nozzle.

(12) When water is drained from the

filter/separator, the float lowers and shuts off the pressure

to the pilot valve C. Pilot valve C opens and flow through

the 3-inch control valve continues.

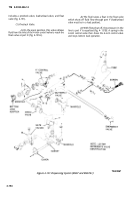

d.

Removal of Control Tubing.

(1)

General.

The general arrangement of the

control tubing is shown in figures 4-153 through 4-155. The

control tubing is nylon and is fastened in various locations

with straps.

4-159

Back to Top