TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 322 of 528

TM 9-2330-356-14

Section IV. REMOVAL AND INSTALLATION OF MAJOR COMPONENTS

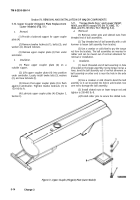

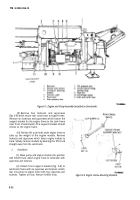

5-10. Upper Coupler (Kingpin) Plate Replacement

(Later Models) (Fig. 5-1)

a.

Removal.

(1) Provide a balanced support for upper coupler

plate

(4).

(2)

Remove twelve locknuts (1), bolts (3), and

washers (2). Discard locknuts.

(3) Remove upper coupler plate (4) from under

semitrailer.

b.

Installation.

(1) Place upper coupler plate (4) on a

suitable support.

(2) Lift upper coupler plate (4) into position

under semitrailer. Loosely install twelve bolts (3), washers

(2), and new locknuts (l).

(3) Ensure that upper coupler plate (4) is flush

against semitrailer. Tighten twelve locknuts (1) to

130-140 lb.-ft.

(4) Lubricate upper coupler plate (4) (Chapter 3,

Section I).

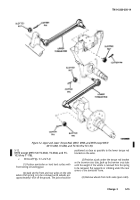

5-11.

Torque Rods (Up r and Lower) M967,

M969, and M970 except 970 SN TC-0843, TC-

0844, and TC-103 thru TC-178) (Fig. 5-2).

a.

Removal.

(1) Remove cotter pins and slotted nuts from

threaded end of ball assemblies.

(2) Tap threaded end of ball assembly with a soft

hammer to loosen ball assembly from bracket.

(3) Use a crowbar or cold chisel to pry the torque

rod from the brackets. The ball assemblies are mounted in

robber and can be moved out of normal alinement for

removal or installation.

b.

Installation.

(1) insert threaded end of ball assembly in hole

of bracket on the bogie assembly. Using torque rod as a

lever, bend the ball assembly out of normal alinement so

ball assembly on other end is near the hole in the axle

bracket.

(2) Use a crowbar or cold chisel to bend the ball

assembly so it can be pushed into hole in axle bracket. Use

care not to damage the ball assembly.

(3) Install slotted nuts on lower torque rod and

tighten to 350-400 lb.-ft.

(4)

Install cotter pins to secure the slotted nuts.

Figure 5-1, Upper Coupler (Kingpin) PIate (Later Models)

5-14

Change 3

Back to Top