TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 329 of 528

TM 9-2330-356-14

5-17.

Bogie Assembly M967A1, M969A1, and

M970A1 including M970 SN TC-0843, TC-0844, and

TC-103 thru TC-178).

a.

Removal.

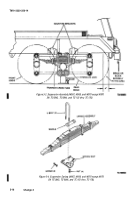

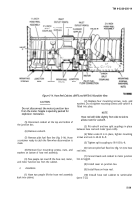

(1) Position semitrailer on hard, level surface

with front resting on landing gear.

(2) Jack up rear of semitrailer and support under

frame securely until weight of semitrailer is removed from

springs and axles (fig. 5-5).

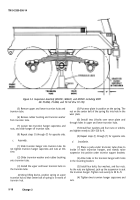

(3) Release air from both air reservoirs by

opening drain cocks on bottom of reservoirs (fig. 4-79).

(4) Tag and disconnect eight hoses from brake air

chambers on both axles. Manually release the fail-safe

springs para 2-4).

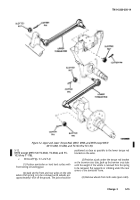

(5) Position a jack under the trunnion tube close

to the inside of each trunnion hanger to support weight of

trunnion tube.

(6) Remove four nuts, four washers, and four

bolts which fasten the trunnion hanger to the mounting

bracket. Repeat for opposite side.

(7) Remove jacks from under trunnion tube.

Raise semitrailer until there is enough clearance to roll

the bogie assembly and wheels out from under rear of

semitrailer (fig. 5-5).

(8) Lower semitrailer onto supports or cribbing

after bogie assembly is removed (fig 5-5).

b.

Installation.

(1) Raise rear of semitrailer to allow bogie

assembly to roll under frame from rear. With front of

bogie assembly toward front of semitrailer, roll bogie

assembly into position under mounting brackets for the

trunnion hangers.

(2) Position a jack under trunnion tube as close as

possible to the inside of each trunnion hanger.

(3) Lower the semitrailer to within l-inch of the

trunnion hangers.

(4) Aline holes in mounting bracket with holes in

trunnion hanger.

(5) Install four capscrews, four washers, and four

nuts. As the nuts are tightened, jack up trunnion tube to

seat the trunnion hanger. Tighten nuts to 90 lb.-ft.

(6) Tighten two trunnion capscrews and nuts.

(7) Repeat steps (4) through (6) for opposite side.

(8) Connect eight hoses to brake air chambers on

both axles as tagged. Manually release the fail-safe springs

(pars 2-4).

(9) Remove jacks and supports, and lower

semitrailer to ground.

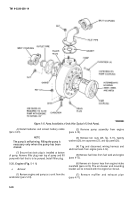

5-18. Engine and Pump Assembly

NOTE

The engino and pump assembly is re-

moved and installed as a unit power plant.

Removal of the complete module is neces-

sary to remove the engine.

The pump can be removed without remov-

ing the complete module.

a.

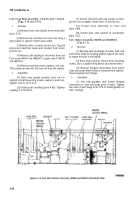

Removal (Fig 5-7).

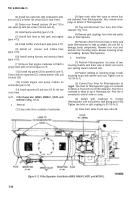

(1) Disconnect negative, then positive battery

cables from batteries (l).

(2) Remove self-tapping screws from muffler

shroud (2). Remove muffler shroud.

(3) Remove the alternator adjusting bracket (3) .

from the alternator to get clearance for removal of

throttle cable.

(4) Loosen wing screws and remove panel door

(5) on air housing. Remove throttle cable (4) (para 4-75).

(5) Remove ¼-inch oil pressure tube (7) for oil

pressure gage from oil adapter. Remove ¼-inch fuel

pressure tube (6) from primary filter. Cut the tie straps,

then pull oil pressure tube and fuel pressure tube from the

engine compartment.

(6) Disconnect control panel wiring harness plug

(8) from junction box on engine frame by turning

counterclockwise with hook-type spanner wrench.

CAUTION

Ensure that fuse has been removed first to

prevent damage.

(7) Disconnect electrical lead for hose reels

(M969, M969A1, M970, and M970A1) above and to right

of fuse (para 4-27). Follow control panel wiring harness

disconnected above, and remove two nuts and capscrews

securing conduit mounting plate to middle of engine

frame behind engine.

(8) Remove split couplings, and disconnect pump

inlet and outlet lines from the centrifugal pump (10).

Change 3

5-21

Back to Top