TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 336 of 528

TM 9-2330-356-14

WARNING

Ensure that forklift is properly positioned

under cabinet. The entire weight of the

cabinet is now on the forklift. Failure to follow

this warning may result In cabinet falling and

injuring personnel.

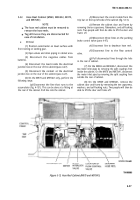

(9) Position a forklift and lift the cabinet slightly

to relieve pressure on the mounting screws and nuts.

(10) Remove eighteen mounting screws and

self-locking nuts (7, top left side; 8, top right side; and 3,

bottom left side).

CAUTION

Before removing the cabinet, ensure that all

disconnections have been made.

(11) Lower the cabinet slightly and pull the lead

from the junction box at the rear of the cabinet.

(12) Remove cabinet.

b.

Installation.

WARNING

Ensure that forklift is properly positioned

under cabinet. The entire weight of the

cabinet is now on the forklift. Failure to follow

this warning may result In cabinet falling and

Injuring personnel.

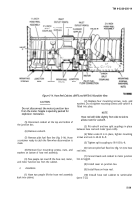

(4) Thread lead to the inside of the junction box

on rear of cabinet.

(5) On the M970 and M970A1, do the following

(fig. 5-13):

(a)

Thread disconnected lines through the

hole at the rear of cabinet.

(b)

Connect line to the flow control valve.

(c)

Connect line to the deadman hose reel.

(d)

Connect three lines to the parking brake

control valve (para 4-47).

(e)

Install cabinet door and frame assembly.

Attach frame to hose trough and cabinet hose with ten

capscrews, flatwashers, and self-locking nuts.

(f)

Connect the control cable to the trip bar

on the top, left side of the cabinet.

(g)

Connect the line that runs to the

accumulator (fig. 4-151).

(6) Connect the conduit to the junction box,

(7) Connect the lead to the inside of the junction

box on the rear of the cabinet (para 4-27).

(8) Connect negative battery cables to batteries.

(9) Operate dispensing equipment and check for

leaks (table 2-1).

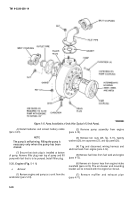

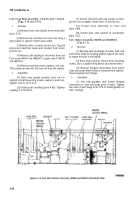

5-23. Hose Reel Assembly-2½-inch (Fig. 5-14)

a.

Removal.

NOTE

NOTE

Ensure that all lines are connected as tagged.

The 2½-inch hose reel, hose reel motor, and

electrical junction box will be removed as a

(1) Position a forklift under the hose reel cabinet.

unit in this procedure.

(2) Position hose reel cabinet under semitrailer

and fasten with eighteen capscrews and self-locking nuts

(7, top left side; 8, top right side; and 3, bottom left side).

Remove forklift.

(3) On M969 and M969A1, install split couplings

to connect both inlet piping to meter inlet tubes

(para 4-85). On M970 and M970A1, install split coupling

behind hose reel cabinet to connect inlet piping to meter

inlet tube.

Tighten split coupling capscrews to

95-105 lb.-ft.

(1) Remove hose reel cabinet from semitrailer

(para 5-22).

(2) Remove 2½-inch hose from reel by releasing

quick disconnect coupling.

(3) Remove cover from motor junction box

(fig. 5-14).

(4) Tag and disconnect leads that enter from the

top and bottom of the box.

5-28

Back to Top