TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 343 of 528

TM 9-2330-356-14

CHAPTER 6

REPAIR OF FRAME AND BODY PARTS

Section I. GENERAL

6-1.

scope

This chapter contains instructions for repair and

replacement of frame and body parts, including the bogie

assembly, which are beyond the scope of the using

organization. These repairs, with the exception of repairs

to tank body or main frame, are allocated to direct support

maintenance. Particular attention must be given to proper

purging of the tank before repairs are made (Chapter 4,

Section XX).

6-2.

Reference

a.

Safety.

Ensure that all safety precautions listed in

the Warning Summary are followed while performing

maintenance. Pay close attention to all WARNINGS and

CAUTIONS.

b.

Procedures.

Procedures for repairs involving

welding, surface preparation, cleaning, and painting are

included under General Maintenance Procedures

(para 5-8).

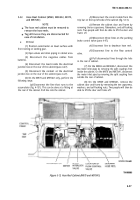

Section Il. BODY ASSEMBLY AND SUSPENSION

6-3.

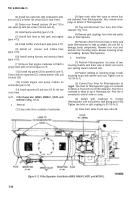

Spring Seat Bearings, Wiper and Seals

M967, M969 and M970 except M970 SN TC-0843,

TC-0844, and TC-103 thru T-178).

a.

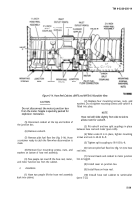

Disassembly.

(1) Remove suspension spring (para 5-12).

(2) Remove six screws (1) and washers (2) from

cap (3). Remove cap and gasket (4).

(3) Remove jam nut (5), key washer (6), and

bearing adjusting nut (8) from end of trunnion cross tube

(30).

(4) Tap the spring seat with a soft hammer to

loosen outer bearing cone (9). Remove the bearing cone

and spring seat (12). Inner bearing cone (16) and seal

assembly (17) will remain in seat. With offset screwdriver,

pry seal assembly out of spring seat. Remove inner bearing

cone. Do not remove packing retainer (18), felt seals, seal

retaining washer, or wiper seal from trunnion cross tube

unless damaged.

(5) If bearings are being replaced, use a bearing

puller or a hammer and punch to remove bearing cups (10

and 15) from spring seat. The bearing cone and cup must

always be replaced as an assembly.

b.

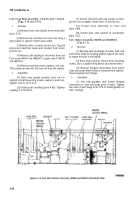

Cleaning and Inspection.

WARNING

Dry cleaning solvent P-D-680 is toxic and

flammable. Always wear protective goggles

and gloves, and use only in a well-ventilated

area. Avoid contact with akin, eyes, and

clothes, end DO NOT breathe vapors. DO

NOT use near open flame or excessive heat

The solvent’s flash point is 100°F-138°F

(38°C-59°C). If you become dizzy while

using cleaning solvent immediately get fresh

air and medical help. if solvent contacts eyes,

immediately wash your eyes with water and

get medical aid.

(1) Clean spring seat, spindle of trunnion cross

tube, and bearings with dry cleaning solvent (item 11,

Appendix E). Use soft bristle brush to remove old

lubrication.

(2) Inspect seat for cracks or damage. Inspect

bearing cups and replace if worn, pitted, or scored.

(3) Apply thin coating (not over 1/16-inch thick) of

grease (item 17, Appendix E) to inside of seat and to

spindle of tube.

(4) Inspect bearing cones for serviceability and

lubricate as specified in Section I of Chapter 3.

(5) Inspect oil seal (17) for damage or lack of

pliability of sealing material.

c.

Assembly (Fig. 6-1).

(1) Install packing retainer (18), oil seal (19), and

wiper (20) onto trunnion cross tube (30) if removed during

disassembly.

(2) If bearing cups (10 and 15) were removed,

press new cups into spring seat.

Change 3

6-1

Back to Top