TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 352 of 528

TM 9-2330-356-14

(5)

(10).

(6)

key (12).

(7)

(8)

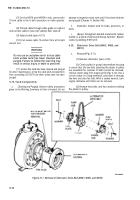

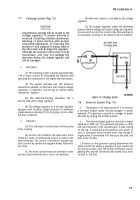

Figure 6-9. Landing Gear Leg.

Remove locknut (9) from shaft on lower leg

Using a puller, remove bevel gear (11) and

Remove screw bushing (13).

Secure upper leg (5) and pull lower leg (10)

from upper leg.

(9) Remove thrust bearing (14) and screw

bushing (15) from shaft on lower leg.

6-10

(10) Remove ring seal (16) from lower leg.

c.

Cleaning, Inspection, and Repair.

WARNING

Dry cleaning solvent P-D-680 Is toxic and

flammable. Always wear protective goggles

and gloves, and use only in a well-ventilated

area. Avoid contact with skin, eyes, and

clothes, and DO NOT breathe vapors. DO

NOT use near open flame or excessive heat.

The solvent’s flash point Is 100°F-138°F

(38°C-590°C). If you become dizzy while

usingcleaning solvent, Immediately get fresh

air and medical help. if solvent contacts eyes,

immediately wash your eyes with water and

get medical aid.

(1) Clean all metal parts in dry cleaning solvent

(item 11, Appendix E) and dry thoroughly.

(2) Inspect the thrust bearing. Replace corroded

or pitted bearing. Revolve bearing slowly by hand. Replace

bearing which has rough or tight spots.

(3) Inspect all gears for nicked, cracked, scored,

broken, or worn teeth. Remove burrs or nicks from gear

teeth with a soft honing stone or crocus cloth (item 4,

Appendix E). Replace badly damaged or worn gears.

(4) Inspect seals for damage. Replace worn or

damaged seals.

d.

Assembly (Fig. 6-9).

(1) Install ring seal (16) onto lower leg (10).

(2) Install screw bushing (15) and thrust bearing

(14) onto shaft of lower leg. Coat bearing with grease

(item 11, Appendix E).

(3) Slide lower leg into upper leg until thrust

bearing (14) is seated against internal bracket inside of

upper leg.

(4) Install screw bushing (13) onto shaft of lower

leg.

(5) Install bevel gear onto shaft and aline key

ways. Install key (12).

(6) Push pinion shaft (4) through seal (6) until it

protrudes into the upper leg. Install washer(8) and pinion

gear (7) onto the pinion shaft. Push shaft through other

seal (6).

(7) Aline holes in pinion shaft and pinion gear,

and install roll pin (3). Be sure pinion gear(7) meshes with

the bevel gear (11).

Back to Top