TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 361 of 528

TM 9-2330-356-14

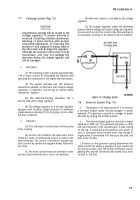

7-7.

Charging System (Fig. 7-5)

CAUTION

Instantaneous damage will be caused to the

voltage regulator if system polarity is

reversed. Installing a battery backwards,

boosting or jump starting with jumper

connected backwards, or reversing the

positive (+) and negative (-) output leads of

the alternator will damage the regulator.

Although the polarity reversal may only be

momentary, and may not damage the

alternator diodes, the voltage regulator will

still be damaged.

a.

Description.

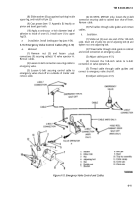

(1) The charging system supplies approximately

14V of direct current for recharging the batteries and

operating the components of the engine electrical system.

(2) The system includes two 12V batteries

connected in parallel, an alternator with integral voltage

regulator, a voltmeter, and wiring to connect these

components together.

(3) The self-load-limiting alternator has a

built-in solid state voltage regulator.

(4) The voltage regulator is a “J’’-type regulator

equipped with transient voltage protection to withstand

instantaneous opening of the charging circuit under

full-load conditions.

b.

Operation.

(1) The alternator is belt driven off the pump

drive coupling.

(2) As the rotor (field) of the alternator turns

inside the stator, an alternating current is made in the

stator windings. The current is rectified or changed into

direct current by positive and negative diodes fastened to

the stator.

(3) The direct current leaves the alternator at the

positive output terminal and is sent to the batteries.

(4) Alternator output is controlled by the voltage

regulator.

(5) The voltage regulator senses the difference

between battery voltage and output voltage and regulates

the amount of current that is sent to the field windings in

the alternator according to the demand from the batteries.

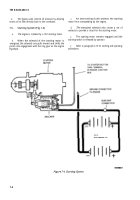

Figure

7-5.

Charging System.

7-8.

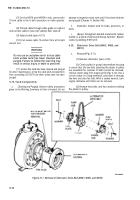

Governor System (Fig. 7-6)

a.

The

purpose of the engine governor is to maintain

a constant engine speed during changes in power

demands. The governor responds to changes in power

demands by varying the throttle position.

b.

The

constant-speed governor maintains engine

speed up to 2400 rpm. The speed-sensing device is a ball

and cup mechanism on the camshaft gear. A yoke, resting

on the cup, is connected to the governor arm which, in

turn, is connected to the throttle lever. Any change in

engine speed is transmitted from the cup to the yoke, and

then to the throttle.

c.

Tension on the governor spring determines the

speed at which the engine is governed. A stud screwed into

the spring is used to vary the number of effective cots for

getting the desired sensitivity-the speed drop from

no-load to full-load.

7-5

Back to Top