TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 359 of 528

TM 9-2330-356-14

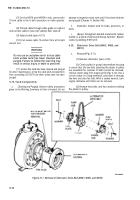

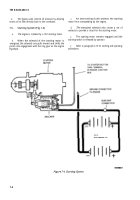

e.

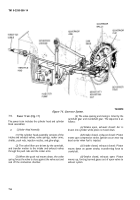

A cam and gear on the camshaft drive the fuel

injection pump. The gear drives the pump face gear,

providing fuel distribution to each cylinder in the proper

order. The cam operates the pump plunger, pressurizing

fuel to the nozzles.

f.

A control sleeve meters fuel by controlling the

length of time the plunger spill port is closed, maintaining

pressure, and therefore, the amount of fuel delivered in

each stroke.

g.

The pintle-type injection nozzles are

conventional inward opening with adjustable opening

pressure. They are factory adjusted to open at

1900-1950 psi.

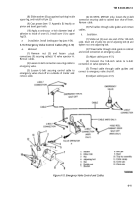

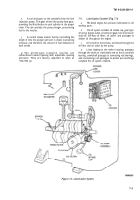

7-5.

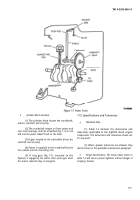

Lubrication System (Fig. 7-3)

a.

The

diesel engine has pressure lubrication to all

working parts.

b.

The

oil system includes oil intake cup, gear-type

oil pump, bypass valve, oil pressure gage, low oil pressure

shut-off, full-flow oil filter, oil cooler, and passages to

deliver oil throughout the engine.

c.

Oil is held in the oil base, and forced through the

oil filter and oil cooler by the pump.

d.

Lines leading to the reeker housing, passages

through the block to crankshaft and to front camshaft

bearing, crankshaft passages to connecting rod bearings,

and connecting rod passages to piston pin bushings

complete the oil system network.

Figure 7-3. Lubrication System.

7-3

Back to Top