TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 349 of 528

TM 9-2330-356-14

Section IV. FRAME AND BODY PARTS

6-11.

Frame, Bumpers, and Brackets

a.

Repair.

(1) Observe all applicable safety precautions

listed in the Warning Summary if the possibility of creating

sparks exists.

(2) All repairs should be done outside where

adequate ventilation and circulation of air will prevent

fuel vapor accumulation.

(3) Repair of minor damage such as straightening

of bent or dented parts can be accomplished with a pry bar

or anvil and heavy hammer.

b.

Replacement.

Frame and body parts that are

integral parts of the semitrailer require replacement of

the next higher assembly (TM 9-2330-356-24P).

6-12. Hose Troughs

a.

Repair.

Repairs are limited to straightening and

removal of dents (para 6-11).

b.

Replacement. The

hose troughs are welded to the

tank and require replacement of the next higher assembly

(TM 9-2330-356-24P).

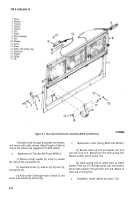

6-13. Piping Control Cabinet

a.

Removal.

(1) Refer to paragraphs 4-84,4-85, and 4-91, and

remove piping and valves inside cabinet.

(2) Remove hose reel cabinet (M969, M969A1,

M970, and M970A1) (para 5-22).

(3) Position lift truck forks or dolly jack under

piping control cabinet to take up weight. Remove cabinet

mounting screws and nuts and remove cabinet.

b.

Repair.

Straighten bent or dented metal. Repair

cracks by welding (TM 9-237).

c.

Installation.

(1) Position cabinet under semitrailer and install

mounting screws and nuts.

(2) Install hose reel cabinet (M969, M969A1,

M970, and M970A1) (para 5-22).

(3) Install valves and piping (para 4-84,4-85, and

4-91).

6-14. Control Panel Assembly

a.

Removal.

(1) Remove all gages, controls, and instruments

from control panel assembly (para 4-24).

(2) Remove panel mounting screws and panels.

b.

Repair.

If control panel cannot be repaired by

straightening or welding, replace the control panel.

c.

installation.

(1) Position control

install mounting screws.

(2) Install decals,

controls (para 4-24).

panel on semitrailer and

gages,

instruments, and

6-15. Hose Real Cabinet (M969, M969A1, M970,

and M970A1)

a.

Removal.

Refer to paragraph 5-22.

b.

Repair.

Straighten bent or dented metal. Repair

cracks by welding (TM 9-237).

c.

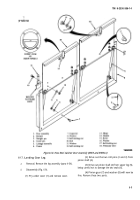

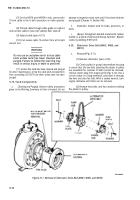

6-16.

a.

b.

frame.

Installation.

Refer to paragraph 5-22.

Cabinet Door (M969, M969A1, M970, and

M970A1 ) (Figs. 6-7 and 6-8)

Removal.

Remove cabinet door (para 5-22).

Repair.

(1) The door hinge is tack welded to the door

Break the tack weld with a steel chisel and grind

surfaces smooth.

(2) Attach new door to door frame by tack

welding in same locations as original welds.

c.

Replacement of Latching Cable (M970 and

M70A1).

(1)

Loosen cable clamps at ends of cable, and pull

cable from latches and guides.

WARNING

DO NOT use an acetylene torch to fuse cable

ends unless tank has been cleaned and

purged. Failure to follow this warning may

result in serious injury or death to personnel.

(2) Before installing new cable, fuse the cable

ends with an acetylene torch to prevent unraveling.

6-7

Back to Top