TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 344 of 528

TM 9-2330-356-14

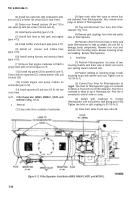

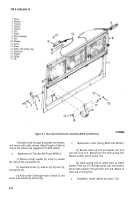

Figure 6-1. Spring Seal and Trunnion Cross Tube Assembly (M967, M969, and M970 except

M970 SN TC-0843, TC-0844, and TC-103 thru TC-178).

(3)

Position inner bearing cone

(16)

in spring seat

and press seal assembly (17) into position. Use wooden

block or discarded seal to press seal squarely into place.

(4)

Slide spring seat (12) onto trunnion cross tube

(30). Hold seat level with tube. With a rocking motion,

push seat carefully into position so seat slides over packing

retainer (18) and oil seal (19) slips over wiper (20) without

damage. Seat should cover retainer when fully positioned.

(5) Install outer bearing cone (9) and bearing

adjusting nut (8). Tighten nut to approximately 25 lb.-ft. to

ensure that bearings seat properly. Back off nut until seat

can be rotated by hand but without noticeable lateral

movement.

(6) Install keywasher (6) on spindle of tube so pin

(7) in bearing adjusting nut (8) engages hole in washer. If

adjustment is not satisfactory, slide washer outward and

turn nut to engage next hole in washer. Install bearing jam

nut (5), tighten, and check bearing adjustment again.

(7)

Install gasket

(4)

and cap (3). Secure cover

with six screws and washers.

(8) Install suspension spring (para 5-12).

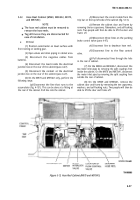

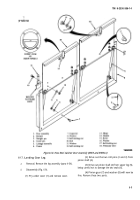

6-4.

Trunnion Cross Tube M967, M969, and

M970 except M970 SN TC-0843 , TC-0844, and TC-

103 thru T-178) (Fig. 6-1).

a.

Removal.

(1) Remove spring and spring seat (para 6-3). Do

this at both ends of trunnion cross tube.

(2)

Remove screw (28) washer (27} and

self-locking nut (26) securing trunnion cross tube to

mounting bracket (22)

on

both ends of tube.

(3)

Remove torque

rods (para 5-11) from

mounting bracket (22) on one end of trunnion cross tube.

Remove four screws (25), washers (24), and nuts (23).

Remove mounting bracket (22).

(4)

Remove trunnion cross tube from opposite

mounting bracket.

6-2

Change 3

Back to Top