TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 348 of 528

TM 9-2330-356-14

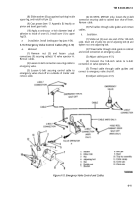

Figure 6-5. Brake Air Chamber (M967, M969, and

M97O except M970 SN TC-0843, TC-0844, and TC-103

thru TC-178) (Fail-Safe Unit).

(4) Remove diaphragm plate (3) and wedge guide

(7) from housing.

(5) Remove collet nut (9).

c.

Cleaning.

Refer to paragraph 6-8.

d.

Inspection and Repair.

Refer to paragraph 6-8.

e.

Assembly.

(1) Perform steps 1 through 4 under para-

graph 6-8.

(2) Assemble fail-safe unit (1) to non-pressure

housing, and secure with clamp ring (6), bolt (4), and nut

(5).

f.

Installation. Refer to paragraph 4-39. Test for

leakage after installation by making full brake application

and applying soapy water around clamp ring and

connections.

6-10. Non-adjusting Brake Plunger M967

M969, and M970 except M970 SN TC-843, TC-

0844, and TC-103 thruTC-178) (Fig. 6-6).

a.

RemovaI.

Refer to paragraph 4-36.

b.

Seal Replacement.

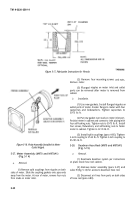

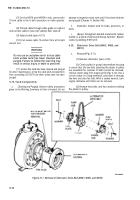

(1) Pry or cut old seal from plunger. Use care not

to damage plunger.

(2) Apply film of grease (item 17, Appendix E) to

inside surfaces of new seal assembly.

(3) Put apiece of masking tape over slot for brake

shoe web in plunger to protect seal during installation.

(4) Carefully push the double-lip seal assembly

onto the plunger. The outer seal lip must be stretched

over nose of plunger. Continue to push on seal until inner

seal is completely in the second plunger groove and outer

seal lip is in the first plunger groove.

(5) Remove masking tape from plunger nose.

c.

Installation.

Refer to paragraph 4-36.

Figure 6-6. Installing Seal on Non-Adjusting Plunger

6-6

Change 3

Back to Top