TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 366 of 528

TM 9-2330-356-14

Table 7-3. Torque Values.

Item

Torque Range (Lb. -Ft.)

Minimum

Maximum

Center main bolt

97

102

Connecting rod bolt

27

29

Rocker-box cover

8

10

Cylinder head bolt

44

46

Exhaust manifold nuts

13

*15

Flyweel mounting screw

65

70

Hub to flywheel.screws

17

21

Fuel pump mounting screws

15

20

Gear case cover

15

20

Glow plug

10

15

Injection nozzle mounting screws

20

21

Injection pump mounting screws

15

16

Intake manifold

13

15

Oil base mounting screws

45

50

Oil pump mounting screws

15

20

Rear bearing plate

40

45

Rocker arm nut

4

Rocker arm stud

35

40

**10

* Exhaust nuts must be tightened evenly.

** This torque is due to friction between the threads only and locks the nuts in

place. Use the rocker arm nut to adjust valve lash.

Section II. REMOVAL AND INSTALLATION OF MAJOR COMPONENTS

7-11.

General

a.

This

section contains step-by-step procedures for

removal and installation of the auxiliary engine major

components and subassemblies.

b.

Do not disassemble the engine beyond the

procedures described in this chapter.

c.

Any further breakdown of the major components

or subassemblies for repair of the engine will be found

under the appropriate headings in Section III, Repair

Instructions.

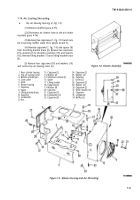

7-12. Preparation

Prior to disassembly of the engine, the following

conditions should be established.

Provide a clean work area. Many diesel engine

parts are intolerant of even minute particles of dirt. A

clean area is required for placement of parts as they are

removed.

b.

Ensure availability of proper cleaning materials

such as solvents, lint-free cloths, soft brushes, pans, waste

containers, etc. Do not use volatile solvents for cleaning.

Diesel fuel is a suitable cleaning solvent, but must be

handled and stored properly.

c.

Refer to table 5-1, Special Tools, Test and Support

Equipment, and ensure that the necessary tools are

available. Always use the right tool for the job; do not

improvise.

7-13. Removal Procedures

a.

General.

(1) Using clean rags and diesel fuel, remove all

grease, oil, and dirt from the engine prior to disassembly.

(2) Remove drain plug and drain crankcase oil

completely. Tip engine toward drain plug side while

draining,

(3) Drain fuel from fuel lines and empty the fuel

sediment bowl.

b.

Removal.

(1) The following paragraphs contain the

instructions necessary to disassemble the engine to

replace damaged or worn components. If each procedure

is followed in order, the engine will be disassembled for

complete overhaul.

(2) Prior to assembly of the engine, certain

inspections and repairs should be accomplished as

described in Section IV, Test and Adjustments.

7-10

Back to Top