TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 326 of 528

TM 9-2330-356-14

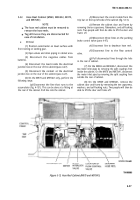

Figure 5-5. Suspension Assembly (M967A1, M969A1, and M970A1 including M970

SN TC-0843, TC-0844, and TC-103 thru TC-178).

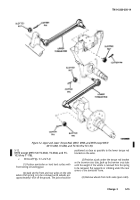

(5) Remove upper and lower trunnion hubs and

trunnion tube.

(6) Remove rubber bushing and trunnion washer

from trunnion tube.

(7) Loosen two trunnion hanger capscrews and

nuts, and slide hanger off trunnion tube.

(8) Repeat steps (1) through (7) for opposite side.

c.

Assembly.

(1) Slide trunnion hanger onto trunnion tube. Do

not tighten trunnion hanger capscrews and nuts at this

time.

(2) Slide trunnion washer and rubber bushing

onto trunnion tube.

(3) Install the upper and lower trunnion hubs on

the trunnion tube.

(4)

Using lifting device, position spring on upper

trunnion hub so that center bolt of spring is in recess of

trunnion hub.

(5) Put wear plate in position on the spring. The

nut on the center bolt of the spring fits into hole in the

wear plate.

(6) Install two U-bolts over wear plate and

through holes in upper and lower trunnion hubs.

(7) Install four washers and four nuts on U-bolts,

and tighten evenly to 200--320 lb.-ft.

(8) Repeat steps (1) through (7) for opposite side.

d.

Installation.

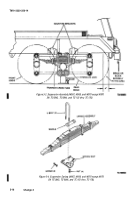

(1) Place a jack under trunnion tube close to

inside of each trunnion hanger, and slowly raise

suspension into position under trunnion support brackets.

(2) Aline holes in the trunnion hanger with holes

in the mounting bracket.

(3) Install four bolts, four washers, and four nuts.

As the nuts are tightened, jack up the suspension to seat

the trunnion hanger. Tighten nuts evenly to 90 lb.-ft.

(4) Tighten two trunnion hanger capscrews and

nuts.

5-18

Change 3

Back to Top