TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 331 of 528

TM 9-2330-356-14

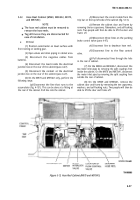

(3) Install split couplings to connect pump inlet

and outlet lines to tank piping (para 4-85).

(4) Attach conduit mounting plate to middle of

engine frame with two screws and locknuts (para 4-25).

Connect wiring harness plug (8, fig. 5-7) to junction box.

Connect electrical lead for hose reels (M969, M969A1,

M970, and M970A1) to buss bar, and install cover.

(5) Install ¼-inch oil pressure tube (7, fig. 5-7) to

oil adapter. Install ¼-inch fuel pressure tube (6) to primary

falter.

(6) Install throttle cable (para 4-75). Install

panel door (5) on air housing. Install alternator adjusting

bracket (3) to alternator.

(7) Install muffler shroud (2) over muffler and

secure with self-tapping screws.

(8) Connect positive,

then negative battery

cables to batteries.

5-19. Centrifugal Pump

a.

Removal (Fig. 5-10).

(1) Remove batteries (para 4-23).

(2) Drain piping. Drain filter/separator (M969,

M969A1, M970, M970A1). Make sure tank is empty of

fuel.

(3) Remove drain plug on bottom of pump and

drain fuel from pump.

(4) Remove pump inlet and outlet lines

(para 4-91).

(5) Remove screws which fasten two halves of

rear firewall (fig. 5-9) to engine frame. Move the

half-sections aside to allow for removal of the pump. Do

not remove the fuel pumps or buss bar assembly from

firewall sections.

(6) Remove alternator (para 4-78).

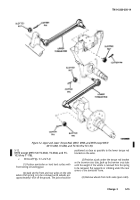

NOTE

It will be necessary to turn engine crankshaft

clockwise with a socket wrench Inserted

through grille on flywheel housing to reach

both capscrews on pump coupling.

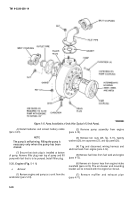

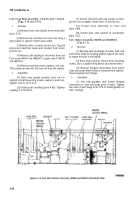

(7) Remove two capscrews and nuts from engine

half of pump coupling (fig. 5-10). The engine half of pump

coupling will remain on engine. The pump half of the

coupling will be removed with the pump.

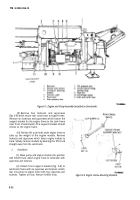

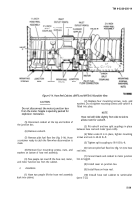

Figure

5-9.

Engine and Pump Assembly Removed From

Semitrailer

(8) Remove two screws and nuts from base of

pump. Mark the location of shims used in pump mounting.

(9) Remove four capscrews and lockwashers

which fasten pump intermediate housing to engine.

(10) Pull pump and intermediate housing straight

away from engine and remove them through rear of

frame.

b.

Installation (Fig. 5-10).

(1) Position pump and intermediate housing on

engine, alining pump half of coupling with engine half of

pump drive coupling.

Install four capscrews and

lockwashers to fasten intermediate housing to engine.

Install two capscrews and nuts to secure two halves of

pump coupling (fig. 5-10).

If Installing same

same positions.

NOTE

pump, use same shims In

(2) Position shims (fig. 5-10) under pump as

required to aline pump mounting with engine mounting to

within .03-inch. Install two screws and nuts, and tighten to

142-158 lb.-ft.

(3) Install pump

inlet and outlet lines

(para 4-90). Use new gaskets on pump mounting flanges.

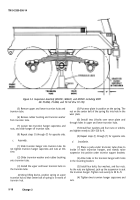

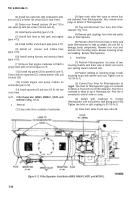

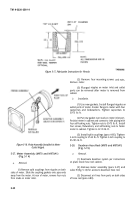

(4) Position half-sections of rear firewall (12 and

14, fig. 5-1 1), and fasten together and to engine frame.

(5) Install alternator (para 4-78).

5-23

Back to Top