TM-9-2350-238-20-1 - Page 787 of 1364

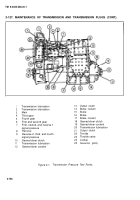

1

2

3

4

5

6

7

8

Install double angle bracket (1) on

transmission (2) and secure with two

machine bolts (3).

If removed, install new identification

marker (4) on double angle bracket (1).

Install drain cock (5) and hexagon plain

nut (6) on double angle bracket (1).

Tighten nut.

Install bushing (7) in transmission (2).

Install adapter (8) in bushing (7).

Install straight adapter (9) in drain cock (5).

Install metal tube assembly (10) and

connect to adapter (8).

Connect metal tube assembly (10) to

straight adapter (9) in drain cock (5).

9

10

11

12

13

TM 9-2350-238-20-1

Install new nonmetallic seal (11), oil filler

strainer element (12), and oil filler gage

rod-cap (13) in transmission (2).

Install new preformed packing (14) on filter

element (15).

Install filter element (15) and new self-

Iocking nut (16) on transmission filter cap

(17).

Install transmission oil pressure fluid filter

(18), new Iockwasher (19), and hexagon

head capscrew (20) in transmission (2).

Install cover (21), and secure with three

new Iockwashers (22) and three hexagon

head capscrews (23).

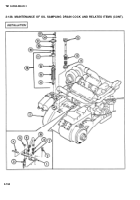

2-129. MAINTENANCE OF FINAL DRIVE ASSEMBLY.

This task covers:

a.

Removal/Disassembly

c. Reassembly/Installation

b.

Inspection/Repair

INITIAL SETUP

Tools and Special Tools

Automotive maintenance and repair shop

equipment: organizational maintenance,

common no. 1 (less power) (item 80,

appx B)

Socket (3/4 in. drive, 1 in.)

Torque wrench (0 to 600 ft-lb)

Wire brush

Final drive lifting sling (item 24, appx G)

Headless shoulder pin (2) (item 16,

appx G)

Hexagon head capscrew (3) (item 22,

appx G)

Hoist

Sling (item 82, appx B)

Matetials/Parts

Compressed air

Dry cleaning solvent (item 16, appx C)

Sealing compound (item 39, appx C)

Self-locking bolt (24)

References

TM 9-2350-238-24P-1

Equipment Conditions

2-873

Tracks removed

2-384 Powerplant removed

2-761

Back to Top