TM-9-2350-238-20-2 - Page 30 of 495

TM 9-2350-238-20- 2

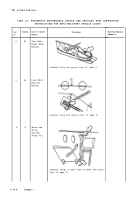

2-7.3 TOOLS AND SUPPLIES (CONT) .

c.

Mandatory Replacement Parts.

The fol -

ment parts that must be replaced durin g

lowing table reflects the mandatory replace-

PMCS whether they have failed or not .

Mandatory Replacement Parts

Item

No.

1

2

Part Number

National Stock

Number

10908813 5330-00-991-8401

MS35338-46 5310-00-637-9541

d.

Lubrication.

The lubrication procedure s

identified in the PMCS table are for unit main-

tenance. Lubrication intervals (on-condition or

hard time) are based on normal operation.

Lubricate more often during constant use or

in severe conditions .

(1)

Use only authorized lubricants iden -

tified in the lubricant table .

(2) Dispose of used lubricants in

accordance with local Standard Operating

Procedure (SOP).

(3) For arctic operation, see FM 9-207.

(4) For desert operation, see FM 90-3.

(5) Clean all grease fittings before attaching

grease gun.

(6) When using grease gun, operate until

grease appears around seals or out of relief valve

and check escaping grease for contamination. If

contamination is found, replace the grease.

Nomenclature Qty

Quarterly

Reservoir

filter and strainer gasket 2

Lockwasher 6

•

NOT E

If no other treatment is

coat unprotected meta l

with CLP (item 5, appx

cleaning .

directed ,

surface s

C) after

•

Clean around filler necks/drai n

pIugs/openings before servicin g

keep dirt from entering system .

t o

(7) Perform a quarterly lubrication as soon

as possible after water fording operation.

ar e

(8) Type of lubricants used at each point

identified by arrows as follows:

(9)

•

•

•

•

Observe the following:

Never use the wrong type of grease.

Never use too much lubrication.

Always clean grease fittings before

lubrication.

Always use the Lubrication Instructions.

2-10. 2

Change 1

Back to Top