TM-9-2350-260-20-1-3 - Page 723 of 783

TM 9-2350-260-20-1-3

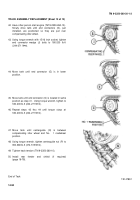

TRACK ASSEMBLY REPLACEMENT (Sheet 10 of 10)

42. Have other person start engine (TM 9-2350-260-10).

Slowly drive tank until end connectors (G), just

installed, are positioned so they are just over

compensating idler wheel.

43. Using torque wrench with 15/16 inch socket, tighten

end connector wedge (J) bolts to 180-200 lb-ft

(244-271 N

•

m).

44. Move tank until end connector (G) is in lower

position.

45. Move tank until end connector (G) is located in same

position as step 41.

Using torque wrench, tighten to

180-200 lb-ft (244-271 N

•

m).

46. Repeat steps 42 thru 44 until torque stays at

180-200 lb-ft (244-271 N

•

m).

47. Move tank until centerguide (N) is between

compensating idler wheel and No.

1 roadwheel

position.

48. Using torque wrench, tighten centerguide nut (P) to

350-380 lb-ft (474-515 N

•

m).

49. Tighten track tension (TM 9-2350-260-10).

50. Install rear fender and shield (if required)

(page 16-78).

End of Task

TA147891

14-90

Back to Top