TM-9-2520-270-34 - Page 235 of 933

TM 9-2520-270-34

CAUTION

Insertion tool must be straight and not allowed

to wobble when installing insert. Equipment

can be damaged.

Do not force insert into tapped hole. Threads

will be damaged.

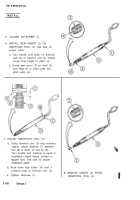

9. INSTALL NEW INSERT (1).

a.

b.

c.

Put tip of insertion tool (2) against

tapped hole (3) being sure that

insertion tool is straight.

Slowly turn handle of insertion tool (2)

to the right until stop collar (4)

contacts body of insertion tool.

If insert (1) does not go into tapped

hole (3) easily, go to step 10. If

insert (1) does go into tapped

hole (3) easily, go to step 13.

10. REMOVE INSERTION TOOL (2).

a. Turn handle of insertion tool (2) to

the left until insertion tool can be

removed.

11. REMOVE DAMAGED INSERT (1).

a. Using needle nose pliers (5), grasp

tang of insert (1) and turn insert to the

left until it can be removed from

tapped hole (3).

b. Remove and discard damaged

insert (1).

12. GO TO STEP 4.

GO TO NEXT PAGE

2-169

Back to Top