TM-9-2815-200-35

ENGINE, WITH CONTAINER:TURBOSUPERCHARGED, DIESEL ,FUEL INJECTION ,90-DEGREE “V” TYPE, AIR - COOLED ,12 - CYLINDER , ASSEMBLY ;MODELS AVDS-1790-2M (2815-856-4996), AVDS-1790-2A AND AVDS-1790-2AM (2815-856-9005)

TECHNICAL MANUAL; DIRECT SUPPORT, GENERAL SUPPORT AND DEPOT MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

TM-9-2815-200-35 - Page 309 of 779

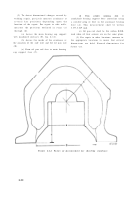

Figure 6-9. Crankcase oil passages-schematic diagram .

(2) Clean the main sleeve bearing halve s

with dry-cleaning solvent or mineral spirits paint

thinner. Use a wooden scraper to remove sludg e

or gum deposits from bearing grooves and oi l

holes. Do not remove the bearing locatio n

markings made during engine disassembly .

d. Inspection .

(1)

Castings.

inspect the crankcase an d

related parts according to instructions covering

castings in paragraph 6-3b and c .

(2)

Miscelaneous metal components.

Refe r

to figure B-2 in Appendix B for parts iden -

tification. Inspect crankcase tie rods (79) and oil

seal retainer (44) for damaged threads and othe r

unserviceable

conditions.

(3)

Inspection of main sleeve bearings .

(a) Inspection of main sleeve bearin g

surfaces

(7.1,

7.2,

7.3,

and

7.4,

fig.

B-3)

is

largely a matter of judgment and experience .

The following instructions will assist in deter -

minin g

whether a bearing is serviceable o r

whether it should be replaced. Replace an y

questionable bearings .

(b) Separation of bearing metal, or sign s

of possible separation , requires that the bearing

be replaced .

6-15

Back to Top