TM-9-2815-200-35

ENGINE, WITH CONTAINER:TURBOSUPERCHARGED, DIESEL ,FUEL INJECTION ,90-DEGREE “V” TYPE, AIR - COOLED ,12 - CYLINDER , ASSEMBLY ;MODELS AVDS-1790-2M (2815-856-4996), AVDS-1790-2A AND AVDS-1790-2AM (2815-856-9005)

TECHNICAL MANUAL; DIRECT SUPPORT, GENERAL SUPPORT AND DEPOT MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

TM-9-2815-200-35 - Page 314 of 779

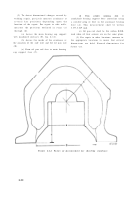

(2) To detect dimensional changes caused by

welding repair, precisely measure crankcase a t

several key positions depending upon th e

location of the repair. For repair to side walls ,

measure the positions outlined in steps (a )

through (d) .

(a) Across the main bearing cap suppor t

web machined surfaces (B, fig. 6-14) .

(b) Across the inside of the crankcase a t

the junction of the side wall and the oil pan rail

(D) .

(c) From oil pan rail face to main bearing

cap support face (C) .

(d)

From

cylinder

mounting

deck

to

crankshaft bearing support bore centerline using

a suitable plug or bore in the crankcase bearing

bore (A). This measurement shall be withi n

8.377-8.369 inch.

(e) Oil pan rail shall be flat within 0.010-

inch when all four corners are on the same plane.

(3) For repair in other locations, measure in

the appropriate locations to insure that critica l

dimensions are held. Record dimensions fo r

future use .

Figure 6-14. Points of measurement for checking crankcase .

6-2 0

Back to Top