TM-9-2815-200-35

ENGINE, WITH CONTAINER:TURBOSUPERCHARGED, DIESEL ,FUEL INJECTION ,90-DEGREE “V” TYPE, AIR - COOLED ,12 - CYLINDER , ASSEMBLY ;MODELS AVDS-1790-2M (2815-856-4996), AVDS-1790-2A AND AVDS-1790-2AM (2815-856-9005)

TECHNICAL MANUAL; DIRECT SUPPORT, GENERAL SUPPORT AND DEPOT MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

TM-9-2815-200-35 - Page 318 of 779

Fig. No.

6-17

6-17

Table 6-3. Crankcase Standard and Oversize Stud Identification - Continued

f. Assembly .

(1)

Preliminary instructions.

Refer t o

general assembly procedures (para 6-6) .

(2)

Position crankcase.

Rotate the engin e

overhaul stand so the crankcase is in the upright

position .

(3)

Install pipe plugs.

Refer to figures 6-5

through 6-7 .

6-10. Overhaul of Transmission Adapter

a. Disassembly .

Disassemble transmissio n

adapter following the sequence of instruction s

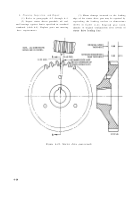

which accompany figure 6-18 .

Remove

1. Cut locking wire and remove four bolts (A) attaching

lifting eye to transmission adapter. Remove lifting eye.

2. Cut locking wire and remove two bolts (B) attaching

timing pointer to adapter. Remove timing pointer.

3. Do not remove the two dowel pins (C) or the two

resilient mounts (D) unless inspection (para 6-3f)

shows replacement is necessary. To remove dowel pins

or resilient mounts, press from adapter using an arbor

press.

Install

1. If dowel pins (C) or resilient mounts (D) were

removed from transmission adapter, install new parts

using an arbor press.

2. Position timing pointer on adapter and install two

bolts (B) securing pointer on adapter. Install locking

wire securing bolts.

3. Position lifting eye on adapter and install four bolts

(A) securing eye on adapter. Install locking wire

securing bolts.

Figure 6-18. Removing or installin g

transmission adapter lifting ey e

and timing pointer .

b. Cleaning, Inspection, and Repair.

Refer t o

paragraphs 6-2 through 6-4 .

c.

Assembly.

Refer to figure 6-18 .

6-24

Back to Top