TM-9-2815-200-35

ENGINE, WITH CONTAINER:TURBOSUPERCHARGED, DIESEL ,FUEL INJECTION ,90-DEGREE “V” TYPE, AIR - COOLED ,12 - CYLINDER , ASSEMBLY ;MODELS AVDS-1790-2M (2815-856-4996), AVDS-1790-2A AND AVDS-1790-2AM (2815-856-9005)

TECHNICAL MANUAL; DIRECT SUPPORT, GENERAL SUPPORT AND DEPOT MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

TM-9-2815-200-35 - Page 311 of 779

compound ,

FSN 9150-663-1770, to th e

threaded area of each main bearing cap stud .

Install a plate washer on each pair of mai n

bearing studs. Install a slotted nut on each main

bearing stud but do not tighten nuts at this time.

(h) Place a surface plate and dial in -

dicator gage on crankcase flange with gag e

indicator resting on end of stud. Measure an d

record height of each stud. Torque tighten main

bearing stud nuts to 500 pound-inches. Alter -

nately tighten all four nuts on each main bearing

to a torque of 700-825 pound-inches. Measur e

the height of each stud after final torque. The

difference between the stud height before an d

after torque tightening, indicates stud stretch .

Normal stud stretch is 0.010 to 0.022-in. If any

stud has stretched more than 0.024-in. at 70 0

pound-inches torque, it must be replaced. Refe r

to table 6-3 when replacing studs .

(i) Install the 14 crankcase tie rods in the

holes provided through the crankcase and main

bearing caps. Equalize the extension of th e

threaded portions of the tie rods on each side of

the crankcase. Apply a small amount of antiseize

compound ,

FSN 9150-663-1770, to th e

threaded portions of each tie rod. Install a plate

washer and a 9 / 16 slotted nut on each end o f

the tie rods .

(j) Starting at the main thrust bearin g

cap, with aid of an assistant to hold the nuts on

the opposit e

side of crankcase ,

alternatel y

tighten all main bearing cap tie rod nuts to 640

pound-inches torque.

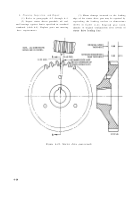

(k) Check the inside diameter of the main

bearings with a dial bore indicator as shown in

figure 6-12 against the limits specified i n

overhaul standards (table 6-2). Replace bearing s

which do not meet these requirements. Ne w

bearings must also be dial bore checked. Remove

the main bearing caps and bearing halves fro m

the crankcase and check contact surface a s

indicated by Prussian blue, FSN 8010-847 -

8706 transfer. Replace bearings that do no t

make 75 percent contact with crankcase bearing

bores. Repeat dial bore check of new bearing s

installed .

Figure 6-12 . Checking inside diameter o f

main bearings .

6-1 7

Back to Top