TM-9-2815-200-35

ENGINE, WITH CONTAINER:TURBOSUPERCHARGED, DIESEL ,FUEL INJECTION ,90-DEGREE “V” TYPE, AIR - COOLED ,12 - CYLINDER , ASSEMBLY ;MODELS AVDS-1790-2M (2815-856-4996), AVDS-1790-2A AND AVDS-1790-2AM (2815-856-9005)

TECHNICAL MANUAL; DIRECT SUPPORT, GENERAL SUPPORT AND DEPOT MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

TM-9-2815-200-35 - Page 310 of 779

(c) Fine scratches on sleeve bearing are

not cause for rejection. Pitting or any other form

of destruction to the bearing surface is cause for

rejection. Replace bearings showing raised meta l

at edges of scratches .

(d) Minute piece s

of metal and dir t

particles embedded in bearing surfaces are no t

cause for rejection .

Note.

Do not attempt to remove suc h

particles. However, if a concentration of em -

bedded particles affects five percent of th e

surface, replace the bearing .

(4)

Stud (tie rod) torque and main bearing

bore inspection .

Note.

Main sleeve bearing halves should b e

their original location in crankcase and mai n

bearing caps .

(d) Check clearance between uppe r

bearing flange and crankcase as shown in figur e

6-11 .

(e) Check clearance between the lowe r

main thrust bearing flange and thrust bearin g

cap in the same manner as shown in figure 6-11.

installed in their original location when they are

to be re-used. Use new bearings when a visua l

inspection indicates bearings are unserviceable .

Use only new or serviceable bearings for main

bearing-bore check .

(a) Refer to figure 6-8 for instructions to

install crankcase on engine overhaul stand .

(b) Check main bearing cap stud torqu e

using a torque wrench as shown in figure 6-10 .

Torque on studs must be 450 pound-inches .

Studs that do not tighten to specified torqu e

must be removed for further inspection. Refer to

table 6-3 when replacing studs .

Note.

Never tighten main bearing stud s

above recommended torque .

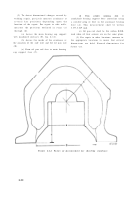

1. Install upper main thrust sleeve bearing (A) into No.

4 main bearing seat of crankcase.

2. Measure clearance between bearing flange and crank-

case using feeler gage (B). Clearance should be 0.0040

to 0.0080-inch.

Figure 6-11. Checking clearance betwee n

upper main thrust bearin g

flange and crankcase .

Figure 6-10. Checking torque of mai n

bearing cap studs .

(c) Spread a thin coat of Prussian blue ,

FSN 8010-247-8706, over steel backs of uppe r

and lower main sleeve bearing halves to show the

sleeve bearing contact surface with the mai n

bearing bore in crankcase. Install bearings i n

(f) Apply a light coating of engine oil ,

Military Specification MIL-L-45199, to the end s

of the seven main bearing caps with sleev e

bearing halves installed. Using crankcas e

spreading tool -

5120-575-7767 as shown i n

figure 5-174 install the bearing caps with bearing

halves in their proper locations in the crankcase.

according to the location number stamped on th e

crankcase and cap. The side of the bearing cap

marked “FLY END” must face the rear of th e

crankcase .

(g) Apply a small amount of antiseiz e

6-16

Back to Top