TM-9-2815-200-35

ENGINE, WITH CONTAINER:TURBOSUPERCHARGED, DIESEL ,FUEL INJECTION ,90-DEGREE “V” TYPE, AIR - COOLED ,12 - CYLINDER , ASSEMBLY ;MODELS AVDS-1790-2M (2815-856-4996), AVDS-1790-2A AND AVDS-1790-2AM (2815-856-9005)

TECHNICAL MANUAL; DIRECT SUPPORT, GENERAL SUPPORT AND DEPOT MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

TM-9-2815-200-35 - Page 335 of 779

NOTE. BEFORE REAMING,

LUBRICATE THREADS ON

CONNECTING ROD BOLTS AND

NUTS WITH THREAD LUBRICANT,

(OR EQUIVALENT) AND TIGHTEN

NUTS TO A TORQUE OF 950 LB-INS.

crankshaft. Right bank rods (marked R) ar e

installed on the damper flange side of journal .

Note.

All location numbers must be visabl e

from the oil pan side when crankshaft and rod s

are installed in the crankcase .

(3) Position connecting rod cap, wit h

bearing installed, on journal and mate it with the

corresponding rod .

Secure rod and cap t o

crankshaft with two slotted nuts .

(4) Tighten nut s

to 950 pound-inche s

torque, plus sufficient additional torque to aline

slots in nuts with cotter pin holes in bolts.

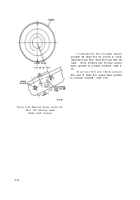

(5) Check the side clearance of each pair of

connectin g

rods against limits specified i n

overhaul standards (table 6-9), using a feele r

gage as shown in figure 6-37. Disassemble and

replac e

connectin g

rod s

and bearings a s

necessary to obtain the proper clearance .

(6)

Secure

slotted

nuts

to

connecting

rod

bolts with cotter pins as shown in figure 6-30 .

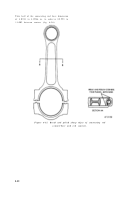

Figure 6-36. Connecting rod bore cente r

dimensions .

6-18. Assembly

a. Crankshaft.

Refer to figure 6-33 .

b. Crankshaft Oil Seal.

Refer to figure 6-32 .

c.

Connecting Rod Assemblies .

Note.

Total weight variation between in -

dividual connecting rods on any one engine shall

not exceed 0.5 ounce .

(1) Position connecting rod bearing halve s

in their respective rods and caps (fig. 6-31) .

Install two connecting rod bolts in each con -

necting rod making certain each bolt is properly

seated in the recess provided .

(2) Position rods on crankshaft in prope r

location according to their identifying number .

Connecting rod Nos. 1R and 1L are assembled

on the journal at the damper flange end of th e

Figure 6-37. Checking connecting rod sid e

clearance .

6-41

Back to Top