TM-9-2815-200-35

ENGINE, WITH CONTAINER:TURBOSUPERCHARGED, DIESEL ,FUEL INJECTION ,90-DEGREE “V” TYPE, AIR - COOLED ,12 - CYLINDER , ASSEMBLY ;MODELS AVDS-1790-2M (2815-856-4996), AVDS-1790-2A AND AVDS-1790-2AM (2815-856-9005)

TECHNICAL MANUAL; DIRECT SUPPORT, GENERAL SUPPORT AND DEPOT MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

TM-9-2815-200-35 - Page 331 of 779

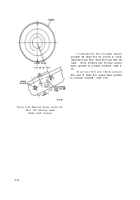

(d) Check dimension between centerline o f

small and large end bores (fig. 6-36). Thi s

dimension must be 10.998 to 11.002 inches. I f

rods do not meet this limit, destroy to insure rods

are not reused in an engine .

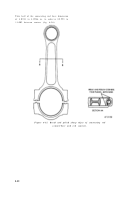

(e) Inspect piston pin sleeve bearing bore

(fig. 6-34) for pitting, galling, scoring, o r

discoloration .

Mark damaged bearings fo r

replacement .

(f) Connecting rods should be matched by

weight. Weight variations between connectin g

rods in an engine should not exceed 0.5 ounce .

Fig

Component

No.

Crankshaft B- 3

B-3

B-3

B-3

B-3

B-3

B-3

B-3

B-3

B-3

B-3

B-3

Ref.

letter

K

M

M-K

P

S

S-P

R

N

N-R

A

B

A-B

Figure 6-34. Checking connecting rod bearin g

bore using dial bore indicator .

Table 6-9. Connecting Rods, Crankshaft and Associated Parts

Overhaul Standards

Note.

Refer to paragraph 6-3b for explanation of symbols.

6-37

Back to Top