TM-9-2815-200-35

ENGINE, WITH CONTAINER:TURBOSUPERCHARGED, DIESEL ,FUEL INJECTION ,90-DEGREE “V” TYPE, AIR - COOLED ,12 - CYLINDER , ASSEMBLY ;MODELS AVDS-1790-2M (2815-856-4996), AVDS-1790-2A AND AVDS-1790-2AM (2815-856-9005)

TECHNICAL MANUAL; DIRECT SUPPORT, GENERAL SUPPORT AND DEPOT MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

TM-9-2815-200-35 - Page 333 of 779

Table 6-9. Connecting Rods, Crankshaft and Associated Parts Overhaul Standards

-

Continued

Fig.

Ref.

Sizes and fits

Component

No.

letter

Point of measurement

of new parts

Wear limits

B-4

RR

Outside diameter of split sleeve bearing must

be press fit in bore. Burnish to seat sleeve

bearing prior to finish diameter

B-4

SS

Inside diameter of bushing-type sleeve bearing

2.0025

2.0027

2.0040

B-4

H

Outside diameter of piston pin

2.0000

2.0002

B-4

SS-H

Fit of pin in bearing

1.9998

0.0023L 0.0027L

0.0042L

Note.

Refer to paragraph 6-3b for explanation of symbols.

6-17. Repair

a. Crankshafts .

(1) Replace crankshafts that are deepl y

scratched, nicked, burred, scuffed or galled .

Minor imperfections in the journals may b e

repaired by polishing with a crocus cloth dipped

in dry-cleaning solvent or mineral spirits pain t

thinner .

(2) Crankshafts that are worn beyon d

standard wear limits specified in the overhau l

standards (table 6-9) or with journal or crank -

case damage may be ground undersize to th e

limits established for crankshaft rework (table 6-

9) .

(3) In the event any of the crankpins o r

journals are found unserviceable, it will b e

necessary to polish or grind all crankpins o r

journals uniformly undersize to maintain th e

balance of the crankshaft. Extreme care must be

taken when regrinding, to maintain the con -

centricity of the entire crankshaft and not t o

exceed a surface roughness of 12 micro inches .

All radii on the crankpins and journals, effected

by grinding undersize, must be re-established to

original configuration .

The crankshaft nitrid e

finish of crankpins and journals must be in -

spected by magnaflux or similar method fo r

fractures and surface cracks after finishing .

(4) Replace dowel pins (18 fig. B-3) an d

straight pins (25) in crankshaft flange if pins do

not fit securely in flange, are out-of-round or if

pins do not conform to limits specified in the

overhaul standards (table 6-9) .

Note.

The headless grooved dowel pins in th e

flywheel end flanges are available in 0.005 and

0.010 in. oversize. Ream crankshaft flywhee l

mounting flange to necessary oversize dimen -

sions and install new pins. Whenever oversiz e

pins are used, it will be necessary to ream the

flywheel and transmission drive gearshaft ac -

cordingly .

(5) Replace a cracked crankshaft or a

crankshaft showing evidence of wear due to bent

or twisted connecting rods .

b. Connecting Rods and Bearings .

(1) Connecting rod bolts .

(a) Replace bolts that do not fit snugly in

rod and cap .

(b) Replace bolt s

that have damage d

threads, galled pilot diameters, or diameters tha t

are not within limits specified in overhau l

standards

(table

6-9).

(c) Replace bolts that are cracked o r

scratched, o r

tha t

sho w

an y

evidence o f

stretching .

(2)

Connecting rod bearings.

Replace al l

bearings that do not check within limits specified

in overhaul standards (table 6-9) or whe n

bearings do not show 75 percent contact b y

Prussian blue transfer after bore check .

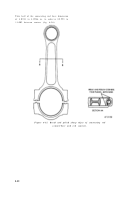

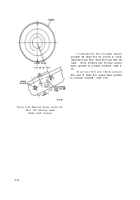

(3) Connecting rod assembly.

Discard con -

nectin g

rod s

that are bent or distorted .

Straightening of connecting rods is not per -

mitted. Break and polish sharp edges at con -

necting rod counterbore and rod contour (fig. 6 -

35). Replace connecting rod assemblies whic h

are not within limits specified in overhau l

standards (table 6-9). Connecting rods wit h

worn or damaged piston pin bearing may b e

repaired. Replace worn or damaged piston pi n

bushing-type bearing using an arbor press .

Bearing split line must be 90 degrees fro m

longitudinal center line. Line-ream new bearing

to size shown in overhaul standards (table 6-9) .

6-39

Back to Top