TM-9-2815-200-35

ENGINE, WITH CONTAINER:TURBOSUPERCHARGED, DIESEL ,FUEL INJECTION ,90-DEGREE “V” TYPE, AIR - COOLED ,12 - CYLINDER , ASSEMBLY ;MODELS AVDS-1790-2M (2815-856-4996), AVDS-1790-2A AND AVDS-1790-2AM (2815-856-9005)

TECHNICAL MANUAL; DIRECT SUPPORT, GENERAL SUPPORT AND DEPOT MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

TM-9-2815-200-35 - Page 330 of 779

c.

Crankshaft .

Remove crankshaft oi l

retaining plugs following instruction s

whic h

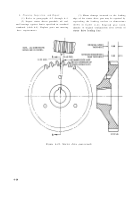

accompany figure 6-33 .

Remove

1. Remove six cotter pins (A).

2. Remove six bolts (B), slotted nuts, and flat washers.

3. Remove 12 retaining plugs (C) from each end of the

bore through the six crankshaft connecting rod jour-

nals.

Install

1. position 12 retaining plugs (C) in each end of the bore

through the six crankshaft connecting rod journals.

2. Install six bolts (B), slotted nuts, and flat washers

securing plugs.

3. Install six cotter pins (A) securing slotted nuts.

Figure 6-33. Removing or installing crank -

shaft oil retaining plugs .

Note.

Do not remove dowel pins (18, fig. B-3)

and straight pins (25) from crankshaft unles s

inspection (para 6-16) indicates replacement i s

necessary .

Dowel pins in flywheel end ar e

secured with setscrews .

6-16. Cleaning and Inspection

a. Cleaning.

Refer to paragraph 6-2. Clea n

crankshaft oil passages with compressed air and

brass wire probes .

Note.

Care must be taken not to destroy o r

remov e

mai n

an d

connectin g

rod bearin g

location markings .

b. Inspection of Crankshaft .

(1) Inspec t

crankshaft for crack s

wit h

magnetic particle inspection equipment o r

simila r

equipmen t

whe n

available .

Whe n

magnetic particle inspection equipment is no t

available use a magnifying glass (five powe r

magnification minimum) and a strong light o r

dye check method. Pay particular attention t o

areas around crankshaft oil holes and fillet s

adjacent to the crank cheeks .

(2) Inspect connecting rod journal radii o f

crankshaft for evidence of specific points of wear

or damages that would indicate a bent or twisted

connecting rod .

(3) Check diameters of main bearing an d

connecting rod journals against limits specified

in overhaul standards (table 6-9). Check run-ou t

of crankshaft by supporting end journals in “V ”

blocks and measuring the run-out at the cente r

journal s

with a dial indicator .

Maximu m

allowable run-out is 0.025 inch at No. 4 journal.

(4) Inspect journals for nicks, burs, grooves.

scratches, galling, scuffing, or discoloration .

Mark minor defect areas for future repair .

(5) Check dowel pins and straight pins fo r

tightness in the crankshaft flanges. Check pin s

against limits specified in the overhaul standards

(table 6-9) .

c.

Inspectio n

of Connecting Rods an d

Bearings .

(1) Connecting rod bearings.

Inspec t

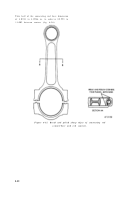

connecting rod bearing halves (fig. 6-31) in the

same manner as described for main sleev e

bearings. Apply a thin coating of Prussian blue ,

FSN 8010-247-8706, to the backs of the con -

nectin g

rod bearing s

an d

install i n

thei r

respective connecting rods and caps according to

the location markings (fig. 6-31). Assemble rod

and cap, and torque tighten nuts to 950-pound -

inches. Check bearing inside diameter, using a

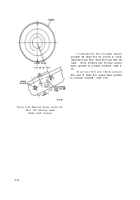

dial indicator as shown in figure 6-34, agains t

the limits specified in the overhaul standard s

(table 6-9) for contact as shown by Prussia n

blue, FSN 8010-247-8706, transfer in the same

manner in which the main sleeve bearings wer e

checked (para 6-9d). Replace any bearing tha t

does not make at least 75 percent contact .

(2)

Connecting rod assembly .

(a) Check connecting rod bearing bore with

a dial indicator against limits specified i n

overhaul standards (table 6-9) .

(b) Check rods for cracks and for twisted or

bent condition. Bent or twisted connecting rod s

must be replaced .

Under no circumstance s

should connecting rods be straightened. Destroy

any rod found damaged to insure it will not b e

reused in an engine .

(c) Inspect for sharp corners at rod bol t

counterbore and contour areas (fig. 6-35). Mark

rods having sharp corners for repair .

6-36

Back to Top