TM-9-2815-200-35

ENGINE, WITH CONTAINER:TURBOSUPERCHARGED, DIESEL ,FUEL INJECTION ,90-DEGREE “V” TYPE, AIR - COOLED ,12 - CYLINDER , ASSEMBLY ;MODELS AVDS-1790-2M (2815-856-4996), AVDS-1790-2A AND AVDS-1790-2AM (2815-856-9005)

TECHNICAL MANUAL; DIRECT SUPPORT, GENERAL SUPPORT AND DEPOT MAINTENANCE MANUAL INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

TM-9-2815-200-35 - Page 329 of 779

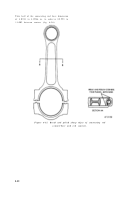

Note.

For location identification connectin g

rods and caps are stamped with a locatio n

number on the side of one of the bosses. Fo r

example ,

“1R” would identify connecting ro d

and cap for No. 1 cylinder on the right bank .

Bearings ar e

also marked to indicate thei r

locations ;

for example ,

the connecting ro d

bearing half for cylinder “1R” is marked “1RR”

and the bearing cap half for the same cylinder is

marke d

"1RC". If the connecting rod, cap, o r

bearin g

marking s

ar e

obliterated ,

restam p

connecting rods, caps, or bearings, so that they

can be installed in their original positions. I n

addition, the connecting rod and cap, which ar e

a matched assembly ,

are marked with iden -

tifying serial numbers. These identifying seria l

numbers are located on the side opposite th e

cylinder location numbers. The rod and ca p

must be kept as a matched assembly, as parts are

not interchangeable .

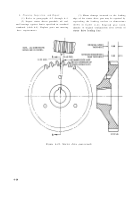

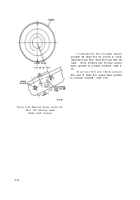

b. Crankshaft Oil Seal.

Remove crankshaf t

oil seal following instructions which accompany

figure 6-32 .

Remove

1. Separate the retaining spring (A) from spring

retaining lip of the oil seal.

2. Disengage the ends of the spring

I(B) at its parting line

with half turn as shown.

3. Separate seal (C) at split line and remove from the

crankshaft. Discard seal and spring.

Install

1. Apply a light coating of automotive and artillery

grease (GAA), FSN 9150-190-0905, to new crankshaft

oil seal (C). Install oil seal on crankshaft with closed, or

flat, side toward flywheel flange.

2. Place a new seal spring (A) around crankshaft as

shown. Turn one end of spring one half turn clockwise

and the other end one half turn counterclockwise. Insert

male end into female end and release spring ends.

Spring ends must be properly engaged.

3. Insert the spring in the retaining groove in the oil seal.

Figure 6-32. Removing or installin g

crankshaft oil seal .

Figure 6-31. Connecting rod and bearin g

identification marks .

6-35

Back to Top