TM-9-2815-205-24 - Page 209 of 856

CLEANING

WARNING

Cleaning solvent is TOXIC and flammable. Wear protective goggles and gloves;

use only in a well-ventilated area; avoid contact with skin, eyes, and clothes; and

do not breathe vapors. Keep away from heat or flame. Never smoke when using

cleaning solvent. Failure to comply may result in injury, illness, or death to

personnel.

Compressed air used for cleaning purposes will not exceed 30 PSI (207 kPa). Use

only with protective equipment (goggles, face shield, gloves, etc.). Failure to

comply may result in injury to personnel.

Wash shell assembly and filter body thoroughly with dry cleaning solvent and dry with compressed air.

END OF TASK

INSPECTION-ACCEPTANCE AND REJECTION CRITERIA

Examine shell assembly for cracks or hardening, replace if defective.

END OF TASK

ASSEMBLY

NOTE

A cast letter “P" (primary) is on top of strainer head.

The filter element, small gasket, and large gasket are provisioned together.

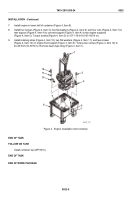

1.

Fuel primary filter assembly (strainer).

a.

Place filter element (Figure 1, Item 15) over center stud in shell assembly (Figure 1, Item 14) and push

down until seated.

b.

Place new large gasket (Figure 1, Item 16) in recess of strainer head (Figure 1, Item 17).

c.

Place new filter element (Figure 1, Item 15) and shell assembly (Figure 1, Item 14) under strainer head

(Figure 1, Item 17) and install new gasket (Figure 1, Item 18) and bolt (Figure 1, Item 19). Tighten bolt

just enough to prevent fuel leakage.

d.

Install drain cock (Figure 1, Item 13) in shell assembly (Figure 1, Item 14).

e.

Install three plugs (Figure 1, Item 20) in strainer head (Figure 1, Item 17).

TM 9-2815-205-24

0031

0031-3

Back to Top