TM-9-2815-205-24 - Page 439 of 856

INSTALLATION

1.

Apply water displacing compound or equivalent to threads and to bolt head contact area (underside) of all

flywheel-fastening bolts (Figure 4, Item 4). Fill threads completely with compound and remove excess.

2.

Thread two guide studs (Figure 4, Item 7) into bolt holes of crankshaft (Figure 4, Item 1).

WARNING

Components of this engine are heavy and awkward to handle. Use correct lifting

procedures, indicated lifting devices, and/or assistance from other personnel. Failure to

comply may result in injury to personnel.

NOTE

Flywheel on model 5063-5299 is heavy. Use two 3/8-16 eye bolts and multiple leg sling to

lift flywheel.

3.

Guide flywheel assembly (Figure 4, Item 2) over guide studs (Figure 4, Item 7) and into bell of

flywheel housing.

4.

Install scuff plate (Figure 4, Item 3) and four self-locking bolts (Figure 4, Item 4). Snug bolts to hold plate

and flywheel assembly in place against crankshaft.

5.

Remove guide studs (Figure 4, Item 7) and install two remaining bolts (Figure 4, Item 4). Snug bolts.

6.

Torque bolts (Figure 4, Item 4) to 48–52 lb-ft (65–71 N·m).

7.

Turn bolts (Figure 4, Item 4) an additional 90–120 degrees to obtain required clamping force.

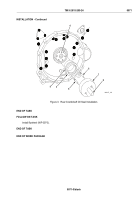

1

3

4

2

7

MODELS

5063-5392

5063-5393

5063-539L

2

7

MAINT_189

Figure 4.

Flywheel Installation.

TM 9-2815-205-24

0070

0070-7

Back to Top