TM-9-2815-205-24 - Page 438 of 856

REPLACEMENT - Continued

2.

Install ring gear (Figure 3, Item 8) on flywheel (Figure 3, Item 9) as follows:

a.

Place flywheel (Figure 3, Item 9), crankshaft side up, on a solid flat surface.

WARNING

Hot metal components dissipate heat quickly. Wear heat-resistant gloves when

handling heated parts. If you receive burns, immerse burn in cold water and seek

medical aid. Failure to comply may result in injury to personnel.

CAUTION

If a torch is used to heat ring gear, keep torch moving around circumference of gear to

avoid hot spots. Do not heat over 400°F (204°C) under any circumstances. Excessive

heat may destroy original heat treatment. Apply heat-indicating compound to work

surface, which melts at a predetermined temperature, to determine heat range.

b.

Place ring gear (Figure 3, Item 8) on a metal surface and heat uniformly. Heat source can be a blow

torch, acetylene torch, or oven.

c.

After ring gear is heated, place it in position on flywheel (Figure 3, Item 9).

NOTE

If ring gear cannot be tapped into place readily, repeat Steps 1–2.c. above.

d.

Tap ring gear (Figure 3, Item 8) into place against shoulder of flywheel (Figure 3, Item 9) using a brass

drift and hammer. Work around circumference of flywheel to avoid binding.

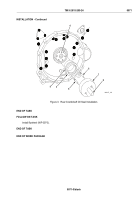

8

9

MAINT_188

Figure 3.

Flywheel Replacement.

END OF TASK

TM 9-2815-205-24

0070

0070-6

Back to Top