TM-9-2815-205-24 - Page 441 of 856

TESTING

1.

Measure flywheel face runout as follows:

a.

Mount flywheel housing gage (Figure 6, Item 11) on flywheel housing (Figure 6, Item 10) with dial

indicator needle against clutch contact face of flywheel (Figure 6, Item 2).

b.

Pry flywheel assembly (Figure 6, Item 2) toward engine block (at six o'clock position) to ensure

endplay is in one direction.

c.

Adjust dial indicator on flywheel housing gage (Figure 6, Item 11) to read zero at 12 o'clock position.

CAUTION

When using hexagon head bolt at front of crankshaft to rotate crankshaft, always turn

bolt clockwise. Serious engine damage may result if bolt becomes loose.

d.

Rotate crankshaft and record readings at 60 degree intervals (six readings). Pry flywheel assembly

(Figure 6, Item 2) toward engine block before taking each reading.

NOTE

Runout is the maximum negative reading plus the maximum positive reading.

For example, if maximum readings were 0.004 inch (0.102 mm) and

-0.007 inch (-0.178 mm), then runout is 0.011 inch (0.280 mm).

Maximum allowable runout is 0.001 inch (0.025 mm) per inch (25.4 mm) of

radius. Measure radius from center of flywheel assembly (Figure 6, Item 2) to

dial indicator needle (clutch contact face). For example, if the radius is

12 inches (304.8 mm), then the runout should be less than 0.012 inch

(0.305 mm).

e.

If flywheel face runout exceeds its maximum limit, remove flywheel assembly (Figure 6, Item 2) and

check for dirt or foreign material between crankshaft and flywheel. Mount flywheel assembly. If

readings are still out of limits, replace flywheel assembly.

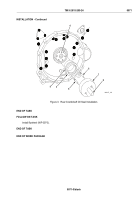

2

2

11

10

12 O′CLOCK

POSITION

12 O′CLOCK

POSITION

MAINT_191

Figure 6.

Flywheel Runout Check.

TM 9-2815-205-24

0070

0070-9

Back to Top