TM-9-2815-205-24 - Page 445 of 856

INSPECTION-ACCEPTANCE AND REJECTION CRITERIA

CAUTION

Do not polish parallel to crankshaft axis or ridges will result in sealing surface and cause

oil leakage.

1.

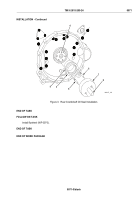

Inspect rear end of crankshaft (Figure 2, Item 4) for wear due to rubbing action of seal, dirt build up, or

fretting by action of flywheel. Remove slight ridges from rear of crankshaft by working around circumference

with crocus cloth wetted with fuel oil.

CAUTION

When using hexagon head bolt at front of crankshaft to rotate crankshaft, always turn bolt

clockwise. Serious engine damage may result if bolt becomes loose.

2.

Check runout of seal bore as follows:

a.

Mount a dial indicator with magnetic base (Figure 2, Item 5) on rear of crankshaft (Figure 2, Item 4).

b.

With an assistant rotating front of crankshaft clockwise, note runout reading. Maximum allowable

runout of bore is 0.008 inch (0.20 mm).

4

5

MAINT_194

Figure 2.

Rear Crankshaft Oil Seal Runout Check.

END OF TASK

TM 9-2815-205-24

0071

0071-3

Back to Top