TM-9-2815-205-24 - Page 580 of 856

TESTING - Continued

g.

Lubricate threads on injector nut (Figure 16, Item 6) with engine oil and carefully thread nut on

pedestal (Figure 13, Item 42). Tighten nut as tight as possible by hand.

h.

Using injector fuel line open end wrench (Figure 13, Item 11), torque injector nut (Figure 16, Item 6) to

75–85 lb-ft (102–115 N·m) for blued components, 45–55 lb-ft (61–75 N·m) for steel gray components,

or 60–70 lb-ft (81–95 N·m) for mixed components.

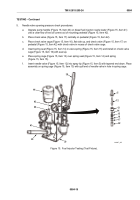

WARNING

Do not operate diesel fuel injector nozzle tester without shield. Fuel spray can

penetrate skin. Fuel oil entering blood stream may cause serious infection. Failure to

comply may result in injury, illness, or death to personnel.

i.

Place shield (Figure 16, Item 44) on diesel fuel injector nozzle tester (Figure 16, Item 41). Operate

pump handle (Figure 16, Item 40) with smooth even strokes and record fuel injector needle valve

opening pressure (pop pressure). Needle valve opens when fuel sprays from tip. Pop needle valve

several times to purge air from system. Record test gage (Figure 16, Item 43) opening pressure. Final

needle valve opening pressure must be 2600–3200 psi (17926–22063 kPa) for new injector and

2300–3300 psi (15857–22752 kPa) for used injector.

j.

Remove injector nut (Figure 16, Item 6), spray tip (Figure 16, Item 5), needle valve

(Figure 16, Item 12), spring (Figure 16, Item 15), spring seat (Figure 16, Item 14), spring cage

(Figure 16, Item 13), check valve cage (Figure 16, Item 16), and check valve (Figure 16, Item 17) from

mounting pedestal (Figure 16, Item 42).

TM 9-2815-205-24

0084

0084-20

Back to Top