TM-9-2815-205-24 - Page 578 of 856

TESTING - Continued

3.

High pressure leak test procedures:

WARNING

Always hold injector so that fuel spray cannot penetrate skin. Fuel oil which

enters blood stream may cause serious infection. Failure to comply may result

in injury, illness, or death to personnel.

Compressed air used for cleaning purposes will not exceed 30 PSI (207 kPa).

Use only with protective equipment (goggles, face shield, gloves, etc.). Failure

to comply may result in injury to personnel.

a.

Thoroughly dry injector with compressed air.

b.

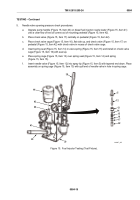

Place injector in diesel fuel injector test fixture (Figure 15, Item 39).

c.

Check fuel connections for leaks. If leaks have occurred, tighten connections, dry injector, and

check again.

d.

With injector rack in FULL FUEL position (fully depressed) and popping handle (Figure 15, Item 38)

locked in downward position, operate pump handle (Figure 15, Item 40) to build up and maintain

pressure.

e.

Pump up injector tester and maintain pressure of 1600 to 2000 psi (11031 to 13789 kPa). Inspect for

leaks at fuel connector ring spacers, injector body plugs, and injector nut preformed packing.

4.

Spray pattern check procedures:

a.

Place injector in diesel fuel injector test fixture (Figure 15, Item 39).

b.

Place injector rack in FULL FUEL position (fully depressed).

WARNING

Do not operate diesel fuel injector nozzle tester without shield. Fuel spray can

penetrate skin. Fuel oil entering blood stream may cause serious infection. Failure to

comply may result in injury, illness, or death to personnel.

c.

Place shield (Figure 15, Item 44) on diesel fuel injector nozzle tester (Figure 15, Item 41). Operate

pump handle (Figure 15, Item 40) to build up slight pressure (10 psi (69 kPa) minimum) in system.

d.

Pop fuel injector several times with popping handle (Figure 15, Item 38). Observe spray pattern

emitted from fuel injector spray tip. If spray tip pattern is not uniform, spray tip orifice is dirty or

damaged.

e.

Pop fuel injector several times with popping handle (Figure 15, Item 38) until no pressure is observed

on test gage (Figure 15, Item 43) to avoid fuel spray when injector is removed from diesel fuel injector

test fixture.

TM 9-2815-205-24

0084

0084-18

Back to Top