TM-9-2815-225-34-P - Page 274 of 736

TM 9-2815-225-34&P

0029 00

0029 00-2

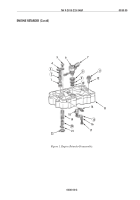

ACCESSORY DRIVE AND ACCESSORY DRIVE PULLEY (Contd)

DISASSEMBLY

1.

Using 3/8 in. (9.525 mm) cold chisel, split and remove sleeve (2) from accessory drive pulley (1).

Discard sleeve (2).

2.

Remove screw (12) and washer (11) from accessory drive shaft (5).

CAUTION

Install screw in accessory drive shaft when using puller.

Failure to do so may result in damage to accessory drive

shaft.

3.

Install screw (12) in accessory drive shaft (5). Using puller, remove spline coupling hub (10) from

accessory drive shaft (5). Remove screw (12) from accessory drive shaft (5).

4.

Remove washer (9) and thrust bearing (8) from accessory drive shaft (5). Discard thrust

bearing (8).

5.

Remove accessory drive shaft (5), with accessory drive gear (3) attached, from accessory drive

housing (6).

6.

Using press and mandrel, remove accessory drive gear (3) and thrust bearing (4) from accessory

drive shaft (5). Discard thrust bearing (4).

7.

Remove two dowel pins (14) from accessory drive shaft (5).

8.

Using press and mandrel,

remove bushing (7) from accessory drive housing (6). Discard

bushing (7).

9.

Remove threaded plug (13) from accessory drive housing (6).

CLEANING AND INSPECTION

1.

For general parts cleaning information, refer to CLEANING, WP 0051 00.

2.

For general parts inspection information, refer to INSPECTION, WP 0051 00.

NOTE

Replace any part that does not pass visual inspection or is

outside specified wear limits.

3.

Inspect front accessory drive pulley (15) and accessory drive pulley (1) for cracks and chips in

hub, worn grooves, and distorted thread holes.

4.

Inspect accessory drive housing (6) for cracks, stripped threads, or damaged holes. Repair any

damaged threads.

5.

Inspect accessory drive gear (3) and spline coupling hub (10) for cracks, chipped or stripped teeth,

and uneven wear.

6.

Using a micrometer or equivalent, measure accessory drive shaft bushing surface outer

dimension (16). Discard accessory drive shaft (5) if accessory drive shaft bushing surface outer

dimension (16) is less than 1.310 in. (3.327 cm).

7.

Inspect accessory drive shaft (5) for elongated dowel pin holes and stripped threads. Repair all

damaged threads.

8.

Inspect two dowel pins (14) for cracks, chips, and distortion.

Back to Top