TM-9-2815-225-34-P - Page 280 of 736

TM 9-2815-225-34&P

0030 00

0030 00-2

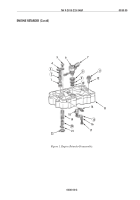

ENGINE RETARDER (Contd)

DISASSEMBLY

WARNING

Control valve cover is under control valve outer spring

pressure. Hold cover securely when removing screws. Failure

to comply may cause injury to personnel.

1.

Remove two screws (5) and control valve covers (4) from brake housing (13).

2.

Remove two outer control valve springs (2) and two inner control valve springs (3) from brake

housing (13). Discard outer control valve springs (2) and inner control valve springs springs (3).

3.

Remove two control valves (1) from brake housing (13).

4.

Disconnect electrical harness (7) from solenoid valve (6).

5.

Using solenoid valve wrench, remove solenoid valve (6) from brake housing (13).

6.

Remove lower seal ring (10), center seal ring (9), and upper seal ring (8) from solenoid valve (6).

Discard seal rings (10), (9), and (8).

7.

Remove two screws (17), washers (16), master piston springs (15), and master pistons (18) from

brake housing (13). Discard springs (15).

8.

Remove two locknuts (11) from setscrews (12) and brake housing (13). Discard locknuts (11).

9.

Remove two setscrews (12) from brake housing (13).

WARNING

Slave piston spring is highly compressed. Be extremely

careful during disassembly. Personal injury can occur if

spring force is not controlled.

NOTE

Perform steps 10 and 11 to remove two slave piston

assemblies.

10.

Using a C-clamp and deep-welled socket, compress slave piston spring (20) and remove retaining

ring (22) from brake housing (13). Slowly release slave piston spring (20) pressure and remove

C-clamp and deep-welled socket.

11.

Remove slave piston retainer (21), slave piston spring (20), and slave piston (19) from brake

housing (13). Discard spring (20).

12.

Remove electrical terminal (14) from brake housing (13).

13.

Repeat steps 1 through 12 for remaining two engine retarders.

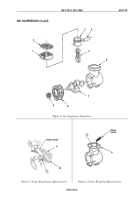

CLEANING AND INSPECTION

1.

For general parts cleaning information, refer to CLEANING, WP 0051 00.

2.

For general parts inspection information, refer to INSPECTION, WP 0051 00.

NOTE

Replace any part that does not pass visual inspection or is

outside specified wear limits.

3.

Inspect slave piston retainers (21) for cracks, breaks, or bends.

4.

Inspect brake housing (13) for cracks, breaks, stripped threaded holes, and scores or scratches in

piston bores. Repair any stripped threaded holes.

5.

Ensure control valves (1), master pistons (18), and slave pistons (19) move freely in the bores.

Replace control valves (1), master pistons (18), or slave pistons (19) if any binding occurs.

Back to Top