TB-9-2350-368-25 - Page 30 of 120

TB 9-2350-368-25

2-16

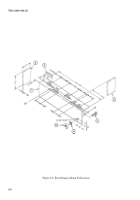

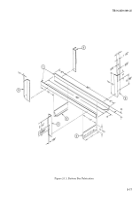

g. Battery Box

Bill Of Materials

Item

Nomenclature

Part Number

NSN

Qty

2” by 2” by 1/4” Steel Angle

1

48 inches (121.9 cm)

2

2” by 3” by 1/4” Steel Angle

2

11-1/4 inches (28.6 cm)

2

2” by 2” by 1/4” Steel Angle

3

15 inches (38.1 cm)

4

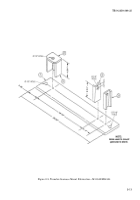

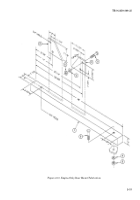

1. Cut two steel angles (1) final length of 48 inches with 45° angle on each end. See Figure 2-11.

2. Cut two steel angles (2) final length of 11-1/4 inches with 45° angle on each end. See Figure 2-11.

3. Weld two steel angles (1) and two steel angles (2) together. See Figure 2-11.

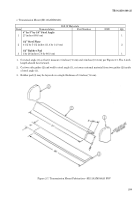

4. On the 3-inch side, scribe a line 7 inches down from the top of steel angle (3) and another 6-7/8 inches

from the 7-inch line.

5. Scribe two lines 5/8 inch on the 3-inch side from each side of steel angle (3).

6. Drill four 9/32-inch holes where the scribed lines intersect, to mount the STE/ICE shunt. See Figure 2-

11.

7. Scribe a line 9-1/4 inches down from the top of steel angle (3) and another 2-53/64 inches down from 9-1/4

inch line. See Figure 2-11.

8. Scribe a line 7/8 inch from edge of steel angle (3). See Figure 2-11.

9. Drill two 7/16-inch holes where the scribed lines intersect, to mount bus bar. See Figure 2-11.

10. Weld four steel angles (3) 12 inches from ends of two steel angles (1) on center tubing. See Figure 2-11.

11. Position and weld four steel angles (3) on the rear cross horizontal tubing, and the other on rear

perpendicular tubing. See Figure 2-11.

Back to Top