TB-9-2350-368-25 - Page 26 of 120

TB 9-2350-368-25

2-12

e. Powerplant Mount Location

Bill Of Materials

Item

Nomenclature

Part Number

NSN

Qty

3” Wide High Density Rubber Pad

1

Adhesive (or similar)

MMM-A-132

Kit

2

26 inches (66.0 cm)

A/R

Hardware

3

Screw

B1821BH750C150N

3

4

Washer

10910174-3

3

5

Nut

MS51922-57

3

6

Screw

B1821BH750C400N

1

7

Screw

B1821BH375C150N

2

8

Washer

10910174-8

3

9

Nut

MS51922-17

3

10

Screw

B1821BH375C550N

2

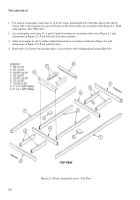

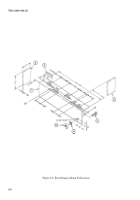

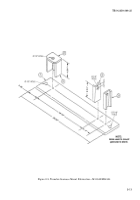

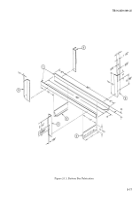

1. Measure 20 inches (50.8 cm) from front of test stand frame along left and right forward spacers. Measure

2 inches (5.1 cm) to the left of the left spacer and mark the intersection of the 20 inch mark. Align the

front edge of the engine mount with the three alignment marks and tack weld to frame. See Figure 2-9.

WARNING

Hanging loads can kill or injure you. Keep away from hanging loads

and overhead equipment. Keep hands out of area while powerplant

is being lifted or lowered on powerplant test stand.

2. Measure 51 inches (129.5 cm) from centerline of welded front engine mount. Scribe a line across frame at

this point. Align transmission mount angle apex with scribed line. Lower a M113A3 powerpack and

connect to front engine mount with two screws (3), washers (4), and nuts (5). Continue to lower

powerpack and align transmission mount with transmission. Tack weld transmission mount. Remove

two screws (3), washers (4), nuts (5) and engine from powerplant test stand. Weld transmission mount

onto test stand frame in accordance with welding specification (ANSI/AWSD1.2). See Figure 2-9.

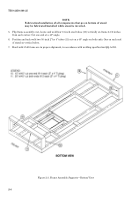

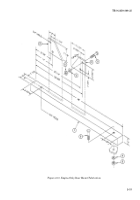

3. Apply adhesive (1) to rubber (2) pad and to surface test stand frame in front of transmission mount.

Allow both surfaces to become tacky. Press rubber pad to test stand frame. Repeat process until a

thickness of 1 inch (2.5 cm) is established.

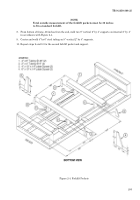

4. Install transfer gearcase mount on either a M113A2 or M548A1 powerpack with two screws (6 and 7),

washers (4 and 8), and nuts (5 and 9).

5. Position M113A2 or M548A1 powerpack on powerplant test stand and secure to front engine mount with

two screws (3), washers (4), and nuts (5).

6. Use gearcase mount as guide, mark holes. Remove powerpack, and drill two 1/2 inch (1.27 cm) holes

through powerplant test stand angle using transfer gearcase mount as a guide for holes. (See Figure 2-8).

Back to Top