TM-9-1240-401-34-P - Page 294 of 590

TM 9-1240-401-34&P

Section VI. General Support Final Inspection Procedures

5.1-23. GENERAL

a.

This section describes and illustrates the final inspection of the M15 quadrant. A final inspection will be performed prior

to returning the M15 quadrant to the using unit or to the supply system.

b.

If the M15 quadrant being inspected fails to meet the required standards, ensure all maintenance authorized at the

applicable level has been performed correctly.

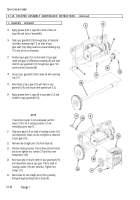

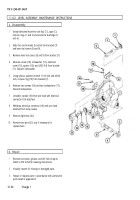

5.1-24. M15 QUADRANT FINAL INSPECTION AND ADJUSTMENT

This task covers:

a.

Setting up and adjusting cross-leveling fixture

b. Visual inspection

c.

Bar (gunner’s quadrant seat) final adjustment

d.

Counter assembly final adjustment

e.

Level assembly final adjustment

f.

Backlash final adjustment

g.

Checking maximum cant angle

h.

Checking cross-level knob running torque

i.

Checking elevation handwheel running torque

j.

Checking knob assembly running torque

INITIAL SET-UP

Test Equipment

Cross-leveling fixture 4931-00-652-3553

Precision level 5120-00-546-6362

Test fixture adapter 4931-00-884-7752

Materials/Parts

Tools and Special Tools

Eccentric tool, fabricated (fig. C-2, appx C)

Quadrant mounting fixture (fig. C-12, appx C)

Shop Equipment, Instrument and Fire Control System

Repair: Field Maintenance, Specialized (SC4931-95

CL-A07) 4931-00-754-0740

Adhesive

Item 1.1, appx B

Sealing compound

Item 13, appx B

Shim stock

Item 19, appx B

Tape, pressure sensitive

Item 20, appx B

5.1-60

Change 1

Back to Top