TM-9-2350-260-20-1-2 - Page 531 of 772

TM 9-2350-260-20-1-2

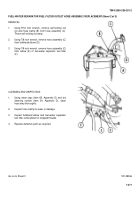

FUEL-WATER SEPARATOR FLUID PRESSURE FILTER REPLACEMENT (Sheet 7 of 7)

14.

Using rags (Item 65, Appendix D), wipe bottom of fuel-water separator filter and connecting lines clean of fuel.

15.

Remove drip pan.

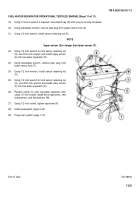

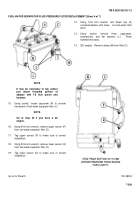

NOTE

If you have replaced fuel-water separator on 2A engine, do steps 2, 7, and 9 thru

12.

If 2D engine fuel-water separator was replaced, do all 12 steps.

TEST:

1.

Perform operational check of automatic drain

(page 7-246).

2.

Connect engine for powerplant ground hop (page

5-54).

3.

Using 7/16 inch wrench, open bleed cap (A).

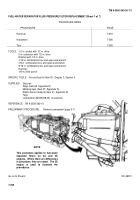

4.

Set FUEL PUMPS switch to ON (TM 9-2350-260-

10).

5.

Set MASTER CONTROL switch to ON (TM 9-

2350-260-10).

Watch bleed cap (A) of fuel water

separator filter (B) for air release (bubbles).

6.

Set MASTER CONTROL switch to OFF (TM 9-2350-260-10).

After about one minute, repeat step 4.

When

constant fuel flow is seen, go to step 7.

NOTE

It may be necessary to perform steps 4 and 5 several times until constant fuel flow

(no bubbles) from bleed cap (A) is observed.

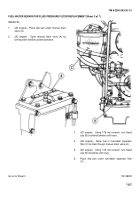

7.

Check for leaks and tighten or replace components as necessary.

8.

Using 7/16 inch wrench, turn fuel-water separator bleed cap (A) to the right until snug.

9.

Set FUEL PUMPS switch to OFF (TM 9-350-260-10).

10.

Set MASTER CONTROL switch to OFF (TM 9-2350-260-10).

11.

Disconnect engine from powerplant ground hop (page 5-67).

12.

Install 2A powerplant (page 5-14) or 2D powerplant (page 5-40).

End of Task

TA148337

7-262

Back to Top