TM-9-2350-311-34-2 - Page 198 of 552

TM 9-2350-311-34-2

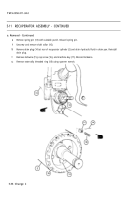

5-11 RECUPERATOR ASSEMBLY

This task covers:

a. Removal

b. Disassembly

c. Inspection

d. Assembly

e. Installation

INITIAL SETUP

Tools

Artillery and turret mechanic ’s tool kit

(SC 5180-95-CL-A12)

Artillery field maintenance tool kit

(SC 4933-95-CL-A06)

Drain pan (item 12, Appx F)

Fabricated breech stand (Figure C-3, Appx C)

Field artillery shop set

Materials/Parts

Adhesive (item 4, Appx B)

Cotter pin (item 47, Appx E)

Cotter pin (item 48, Appx E)

Grease (item 21, Appx B)

Gasket (item 112, Appx E)

Gasket (item 126, Appx E)

Hydraulic fluid (item 22, Appx B)

Lockwire (item 36, Appx E)

Lockwire (item 37, Appx E)

Lockwire (item 39, Appx E)

Piston wiper (item 113, Appx E)

Rag (item 26, Appx B)

Retaining rings (2) (item 103, Appx E)

Seal replacement parts kit (item 152, Appx E)

Self-locking nuts (2) (item 161, Appx E)

Spring pin (item 10, Appx E)

Spring pins (2) (item 6, Appx E)

Webbing strap (item 34, Appx B)

Wooden blocks (V) (item 37, Appx B)

Personnel Required

3

Equipment Condition

Cannon assembly depressed to 0 mils

(TM 9-2350-311-10)

Lower gun shield removed (para 5-1)

a. Removal

Wear safety glasses and steel-tipped safety shoes to avoid possible injury while handling

equipment.

Level cannon before venting nitrogen to avoid serious injury to personnel or damage to equip-

ment caused by cannon assembly sliding out of battery.

Keep all parts of body clear to prevent serious injury when venting nitrogen. High pressure nitro-

gen must be completely vented before the drain plug is loosened to prevent serious injury

caused by escaping hydraulic fluid.

Ensure valves are closed prior to disassembly to prevent sudden release of nitrogen pressure.

Care should be taken to prevent contamination of recuperator cylinder during disassembly and

assembly.

Prior to removing valve cap ensure that the pneumatic valve is closed to prevent release of ni-

trogen pressure. This will prevent serious injury or damage to equipment caused by sudden

release of nitrogen pressure.

5-54 Change 2

Back to Top