TM-9-2350-311-34-2 - Page 247 of 552

TM 9-2350-311-34-2

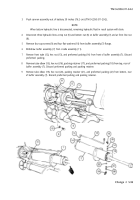

c. Inspection

1

2

3

4

5

6

7

8

9

10

11

12

13

Inspect bumper assembly (23). Replace as an assembly if there are burrs, cracks, sharp edges, or other damage.

Inspect threaded bushings (30) and (44) for burrs or sharp edges. Replace if needed.

Using micrometer calipers, measure inside diameter of machine bushing (32) and sleeve bushing (50). Re-

place if inside diameter is greater than 1.000 inch (2.54 cm).

Inspect piston buffer rod (27) for damage, wear, or tolerance O.D. 0.995 in. (25.273 mm) minimum. Replace

if scored, scratched, or O.D. is 0.995 in. (25.273 mm) minimum. Repair if threads are burred or nicked. Re-

move any paint on piston buffer rod.

Inspect buffer cylinder (28) for damage. Replace if exterior is cracked, dented, or deformed. Replace if inte-

rior is scratched or galled.

Measure inside diameter of buffer cylinder (28) in two places. At 20 inches (50.8 cm) from stop end, replace

if greater than 3.51 inches (8.92 cm). At 8.5 inches (21.59 cm) from stop end, replace if greater than 3.5

inches (8.89 cm).

Inspect linear actuating piston (36) for damage. Replace if nicked, scratched, or burred.

Using calipers, measure outside diameter of linear actuating piston (36). Replace if less than 3.487 inches

(8.857 cm).

Inspect valve (42) for burrs or sharp edges. Replace as required.

Using calipers, measure valve (42) thickness. Replace if less than 0.12 inches (3.05 mm).

Inspect guide (40) for burrs or sharp edges. Replace as required.

Inspect helical compression spring (41). Replace if free length is less than 1.438 in. or is cracked or

distorted.

Inspect helical compression spring (24). Replace if free length is less than 22.25 in. or is cracked or dis-

torted.

Change 2

5-103

Back to Top